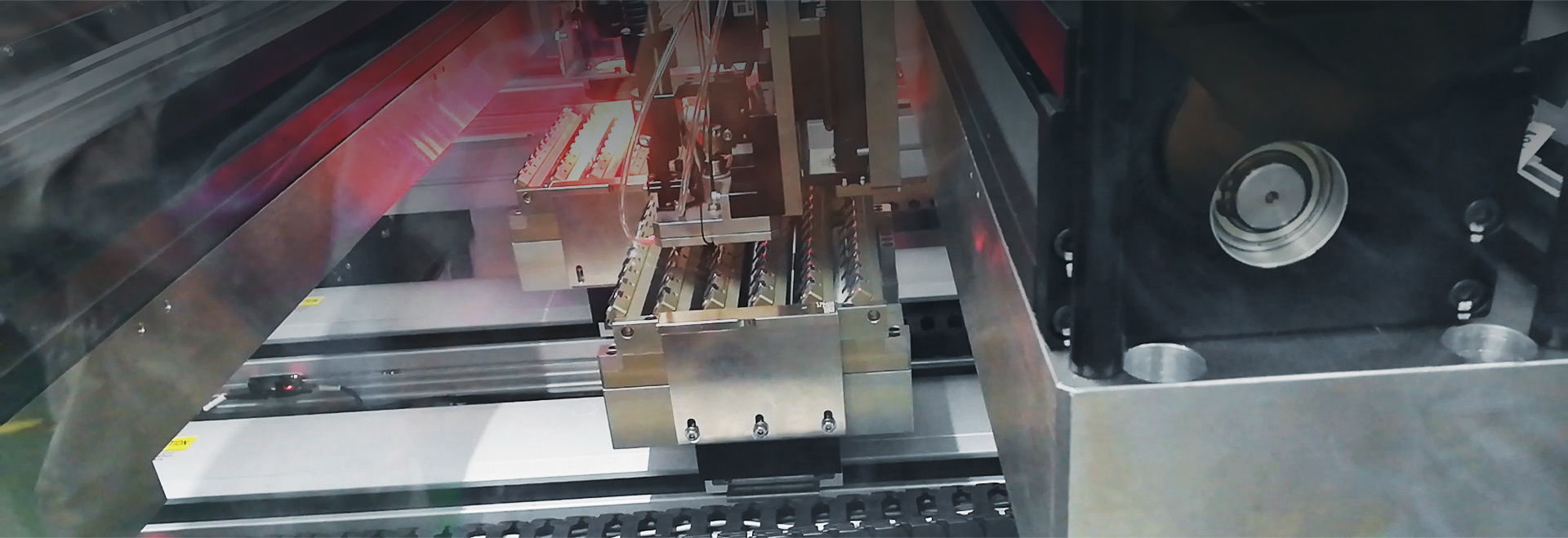

MiniLED\ MicroLED solder rework production and testing machine

Introduction

- Its main function is to remove glue, chips and solder residues from Mini LEDs with poor lighting detection by mechanical grinding + automatic solder paste + automatic replacement of LED parts + automatic laser welding. The whole line has realized the mechanized unmanned operation of the MINI-LED rework requirements. The front and back ends of the equipment can be connected to the docking station, seamlessly connecting with the client process. Modular design, convenient and flexible, can be used as stand-alone and connected.

Technical advantages

- Zero risk after repair welding, no burning phenomenon

- No tombstone, no offset, no missing welding

- Lateral thrust>2N

- It can meet the specifications of 0305, 0406, 0408, 0509, 0620, etc.

- Replenishing crystal speed: 200ms/pcs, pixel 60K/H

- Replenishing crystal precision: ± 15um

- Effective stroke 400*600 (customizable)

Application

Product Feature

Except for manual and automatic loading and unloading, all the functions and data of the other intermediate links are Inline;

Integrate a variety of precision inspection and control functions to ensure grinding accuracy, that is, it can effectively remove bad wafers and residual tin without damaging the pad and PCB, and the height deviation is 0.002μm;

The precise control combination of more than ten sets of linear guides and voice coil motors can achieve solder coating and crystal filling within milliseconds to 0305 wafers, with a position accuracy of 0.005μm;

Applicable laser selection to ensure targeted welding of the points to be processed, so as not to damage the wafer, the pad is not damaged, no erected, no burns.

Technical Parameters

Product Feature

Except for manual and automatic loading and unloading, all the functions and data of the other intermediate links are Inline;

Integrate a variety of precision inspection and control functions to ensure grinding accuracy, that is, it can effectively remove bad wafers and residual tin without damaging the pad and PCB, and the height deviation is 0.002μm;

The precise control combination of more than ten sets of linear guides and voice coil motors can achieve solder coating and crystal filling within milliseconds to 0305 wafers, with a position accuracy of 0.005μm;

Applicable laser selection to ensure targeted welding of the points to be processed, so as not to damage the wafer, the pad is not damaged, no erected, no burns.