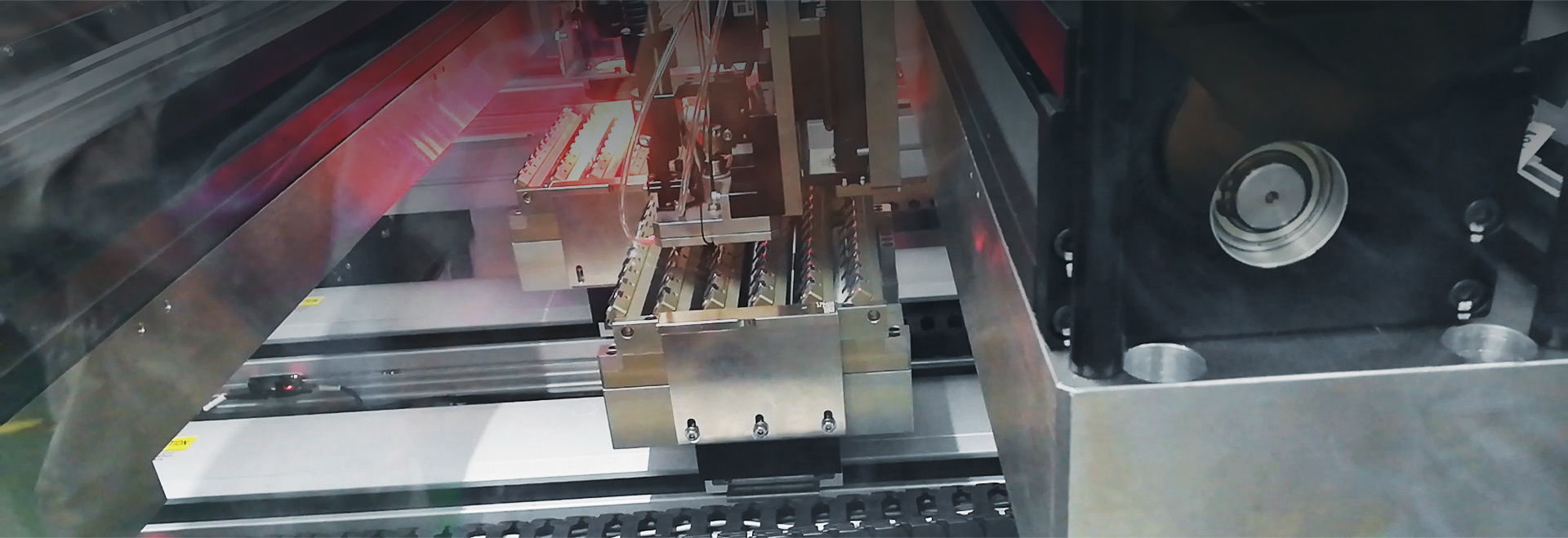

Ultrasonic soldering machine

Introduction

Ultrasonic welding principle: use the mechanical vibration energy of ultrasonic frequency (more than 16KHz) to connect the same metal or dissimilar metal. During ultrasonic welding, the metal neither transmits current to the workpiece nor applies high temperature heat source to the workpiece. But under static pressure, it converts the vibration energy of wire frame into friction work, deformation energy and limited temperature rise between work pieces. Metallurgical bonding between joints is a kind of solid state welding without melting the base metal. Therefore, it effectively overcomes the phenomena of spatter and oxidation produced during resistance welding

Strengths

1. Fast

2. Energy-saving

3. High fusion strength

4. Good electrical conductivity

5. No sparks

6. Close to the cold state processing

Application

1. High-speed communication wire

2. Enameled wire

3. Gold wire bonding welding.

Technical Parameters

1. High-speed communication wire

2. Enameled wire

3. Gold wire bonding welding.