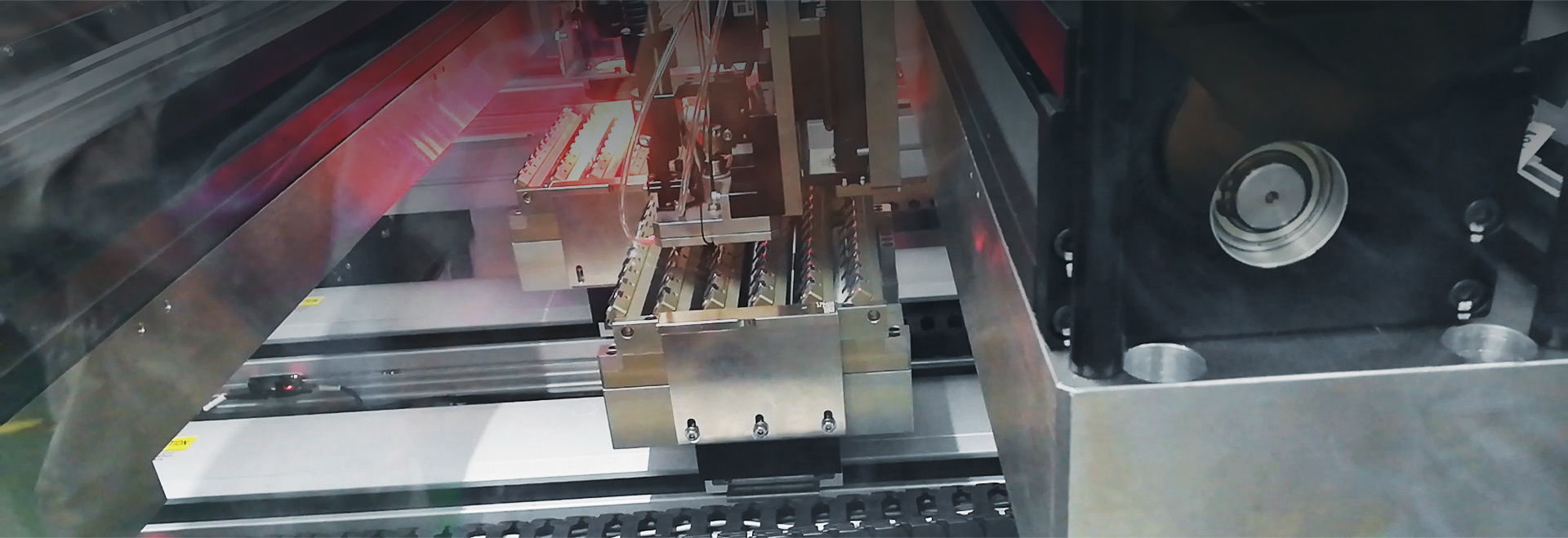

Electromagnetic soldering machine

Introduction

Based on electromagnetic induction heating technology, this product is equipped with a three-axis motion platform and temperature control system, which can realize the welding of thick plate THP devices, surface-mount components and deep-buried hetero-structures, with a wide range of applications, short welding time and high UPH.

Advantange

◆ With temperature control system, it can control constant temperature welding and output real-time temperature control curve.

◆ The welding time is short, and the temperature can be raised to 200 ° C or above instantaneously, with high efficiency and good energy efficiency.

◆ Equipped with three-axis positioning platform to achieve accurate positioning.

◆ It can be used in a wide range of applications, not only for the welding of thick plate pin type devices, but also for the welding of surface mount components such as BGA, mini LED, etc.

Application

◆ Realize the welding of multiple products on one equipment

◆ Thick plate welding of THP elements;

◆ Welding of SMT components;

◆ Welding of heterogeneous structures such as deep buried holes and sandwich solder joints.

Technical Parameters

◆ Realize the welding of multiple products on one equipment

◆ Thick plate welding of THP elements;

◆ Welding of SMT components;

◆ Welding of heterogeneous structures such as deep buried holes and sandwich solder joints.