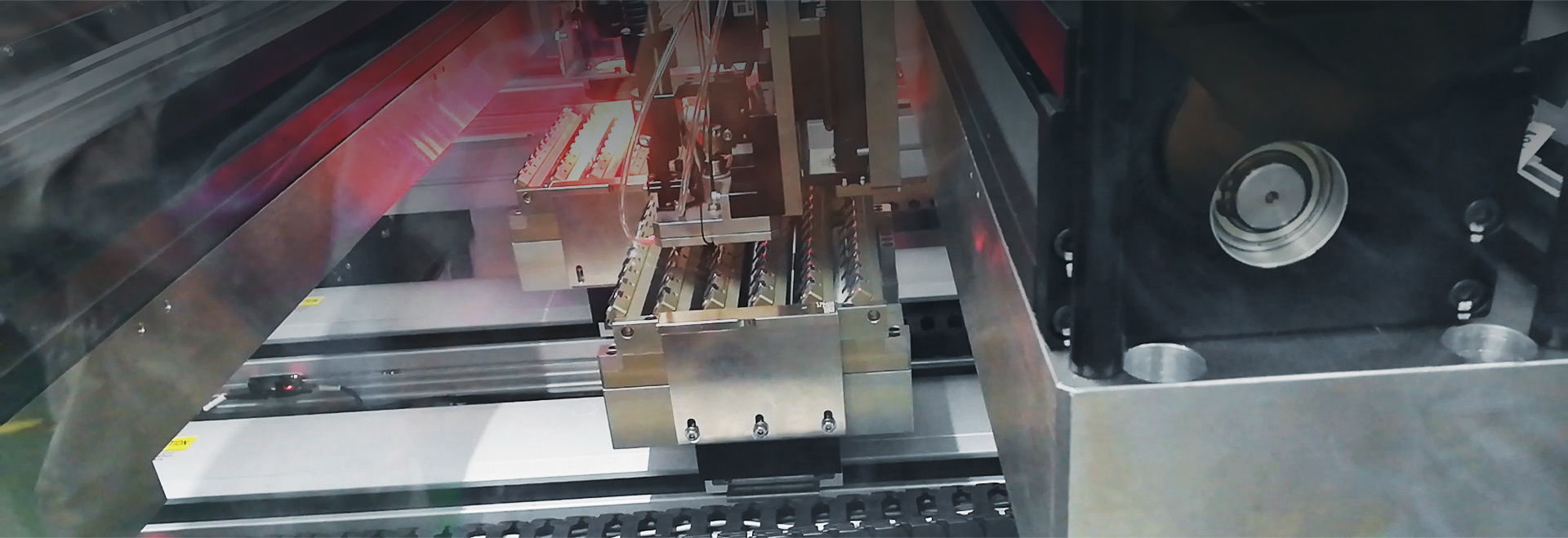

Gold washing & Tin coating machine

Introduction

The gold-washing and tin-coating machine is a kind of surface treatment equipment that removes the gold coating on the pins of components and then tins them. The main purpose of gold plating on component pins and solder ends is to improve the oxidation resistance and wear resistance. However, this gold plating layer is very easy to produce "gold embrittlement" during soldering. If the gold is not removed before soldering, it will cause quality problems and even potential safety hazards, which will seriously affect the quality and reliability of electronic products.

Strengths

1.Highly automatic;

2.Double CCD smart positioning, which can recognize different components;

3.Wide application.

Application

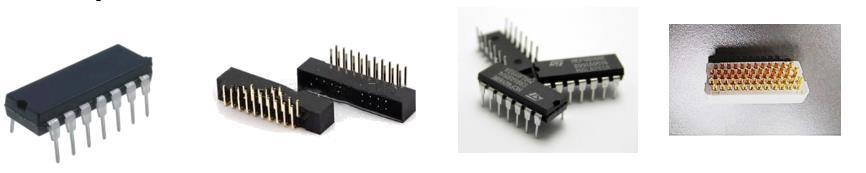

Gold washing & Tin coating of IC, QFP, SOP, QFN, and DIP devices

Applied components features:

1. IC/QFP/QFN, etc.

2. Resistor/capacitor components

3. Minimum pin pitch 0.3mm

4. Minimum size 6*6mm

Plug-in devices with pins

Mounting Devices

Technical Parameters

Gold washing & Tin coating of IC, QFP, SOP, QFN, and DIP devices

Applied components features:

1. IC/QFP/QFN, etc.

2. Resistor/capacitor components

3. Minimum pin pitch 0.3mm

4. Minimum size 6*6mm

Plug-in devices with pins

Mounting Devices