ECON-09F Solder Dross Separator

Introduction

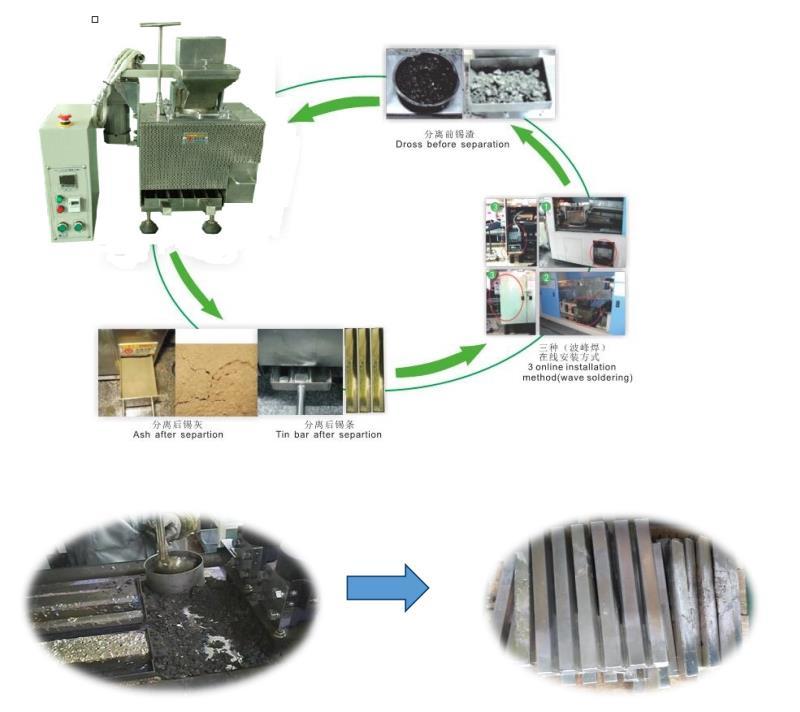

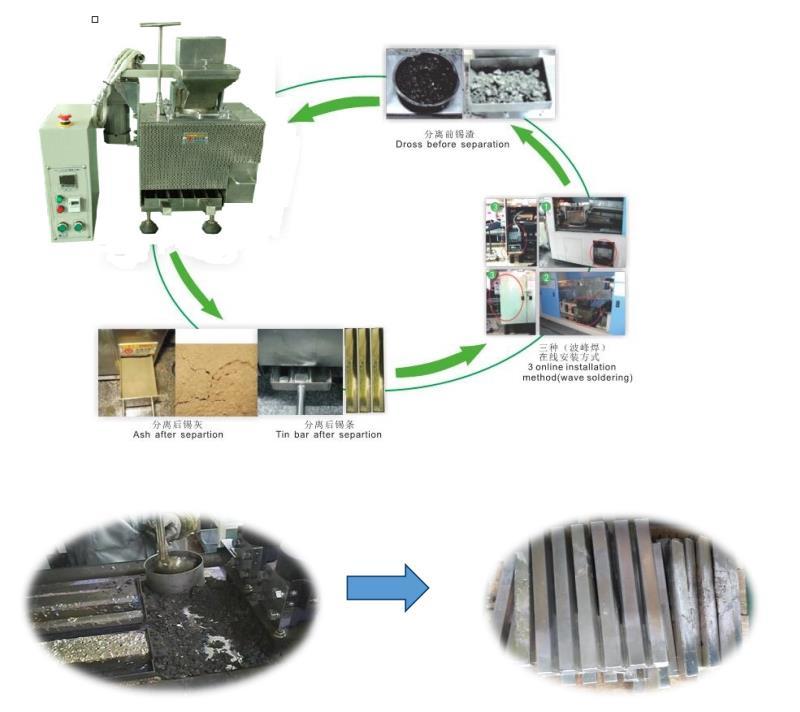

Dross Recovery Machine could recover the oxide (solder dross) generated during the soldering process with physical methods . The purity of solder could reach up to 93.6% and the recycle solder could be used in manufacturing directly. It is cost-saving and environmental-friendly.

Dross recovery machine is one of the main products of Shenzhen Anewbest Electronic Technology Co., Ltd. with products with good price and quality.Our factory is a Best suppliers and Manufacturers china,There are also high-quality custom wholesale prices.

A dross recovery machine is equipment used to recover metal alloys from dross formed during the metal smelting process. Dross refers to the layer of impurities and oxides floated to the surface of molten metals like aluminum, zinc and brass. Dross recovery machines help extract valuable metals trapped within the dross through mechanical impact and separation. They crush the dross into smaller particles to liberate the metal alloys before separating them using methods such as sieving, magnetic separation and density separation.

The dross recovery process involves feeding dross into a crusher to reduce the particle size. The crushed dross then goes through screening and sorting steps to separate metal particles from non-metallic materials. Magnets and eddy currents are used to extract ferrous and non-ferrous metals. The metals are finally collected and recovered for re-melting or sale.

Dross recovery provides both economic and environmental benefits. It reduces the loss of valuable metals to dross and minimizes waste generated from metal processing. The recovered metals can be re-melted to produce new metals or sold as scrap materials. Proper dross management helps companies maximize the yield of metal production and revenue. It also decreases disposal costs from reduced waste and less reliance on landfills.

The dross recovery machines improve productivity and metal reclamation rates in foundries and smelters. The equipment crushes dross into optimal particles for effective separation and metal extraction. Advanced models utilize staged separation techniques and high-intensity magnetic fields to recover up to 95% of metals with minimal operator involvement. Automated dross recovery systems can process several tons of dross per hour with consistent results.

In summary, dross recovery machines provide a mechanized solution to reclaim valuable metals from dross generated during metal processing and production. They help foundries and smelters maximize the yield of molten metal by separating and recovering metals trapped within dross. The dross recovery equipment reduces waste and disposal costs through efficient recycling of metal alloys. Automated and high-capacity dross recovery systems improve productivity with fast processing speeds and high metal recovery rates. By turning dross into a source of reusable metals and revenue, dross recovery machines contribute to sustainable and cost-saving metal manufacturing practices.

Application

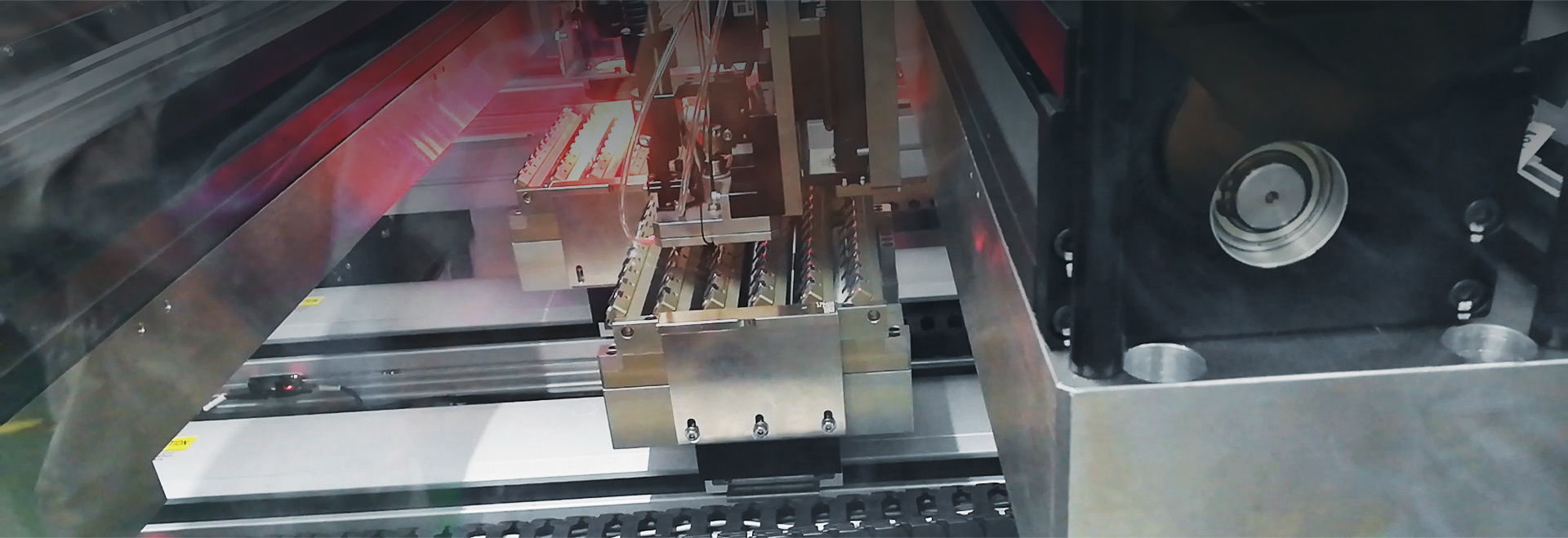

Electronic Manufacturing ..

Strengths

1. Low temperature separation: Heating to 280℃ and then separating pure tin from dross.;

2.Pure physical: No need to add chemicals; mechanical separation; no pollution to solder and no change in solder quality and quantity;

3, Wet separation: Using solder to melt tin dross; no secondary oxidation, static separation, effectively reduce smoke pollution;

4, Tin dross recycling can reduce the waste of 75% tin dross, 90% resources can be recycled.

Technical Parameters

Electronic Manufacturing ..

Strengths

1. Low temperature separation: Heating to 280℃ and then separating pure tin from dross.;

2.Pure physical: No need to add chemicals; mechanical separation; no pollution to solder and no change in solder quality and quantity;

3, Wet separation: Using solder to melt tin dross; no secondary oxidation, static separation, effectively reduce smoke pollution;

4, Tin dross recycling can reduce the waste of 75% tin dross, 90% resources can be recycled.