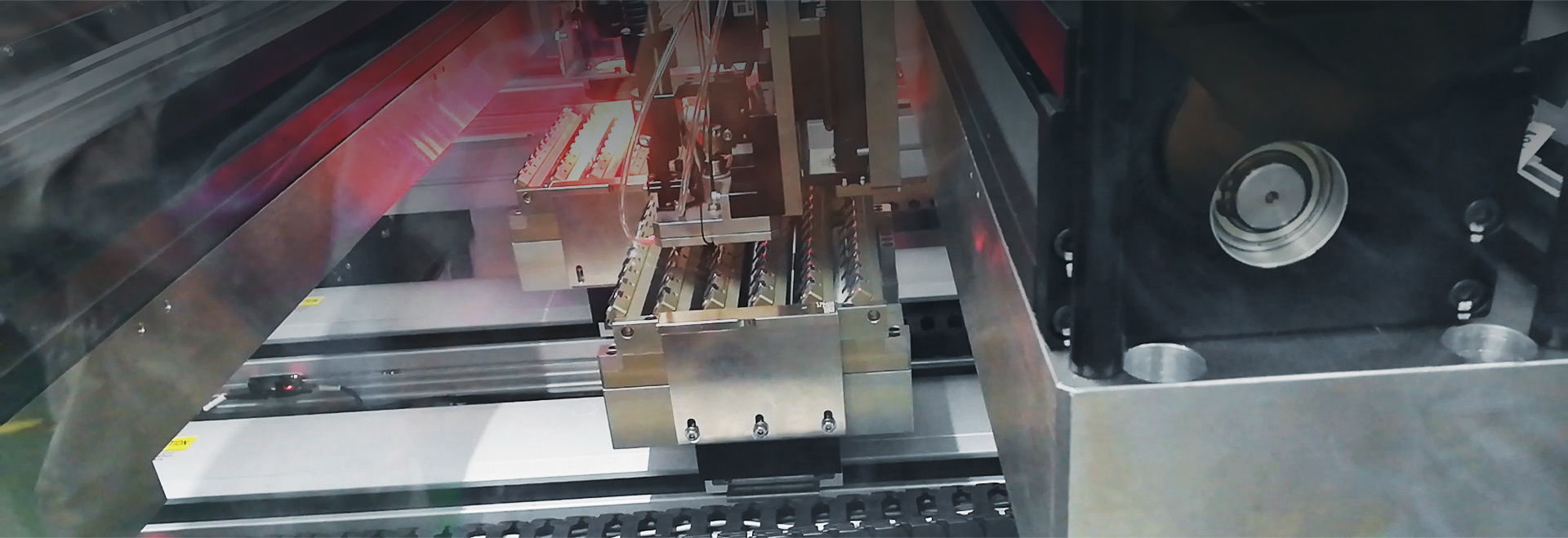

In-line laser solder ball soldering machine

Introduction

- Suitable for high-precision soldering ,precision ±10um ,product mini clearance 100um;

- The range of solder balls can be chosen from a wide range of 0.1mm to 1.8mm in diameter

- Applied to tin, gold, silver coated metal surface, Yield rate above 99% .

Advantange

- Heating and melting process is fast, can be completed within 0.2s.

- Melt the solder ball in the nozzle without splashing;

- No flux, no pollution, to maximize the life of electronic devices

- The diameter of the tin ball is Mini 70um, in line with the development trend of integration and high precision

- The tin content is uniform, fixed point quantitative, and the consistency is good;

Application

◆Micro-electronics industry:high definition camera module,mobile digital camera soft board connection point soldering,precision sound control device,Data wire assembly soldering,sensor soldering.

◆Aerospace high precision electronic products soldering.

◆Other industries:wafer,optoelectronic products,MEMS,sensor production,BGA,HDD (HGA,HSA) ,high precision components,high precision electronic soldering.

Technical Parameters

◆Micro-electronics industry:high definition camera module,mobile digital camera soft board connection point soldering,precision sound control device,Data wire assembly soldering,sensor soldering.

◆Aerospace high precision electronic products soldering.

◆Other industries:wafer,optoelectronic products,MEMS,sensor production,BGA,HDD (HGA,HSA) ,high precision components,high precision electronic soldering.