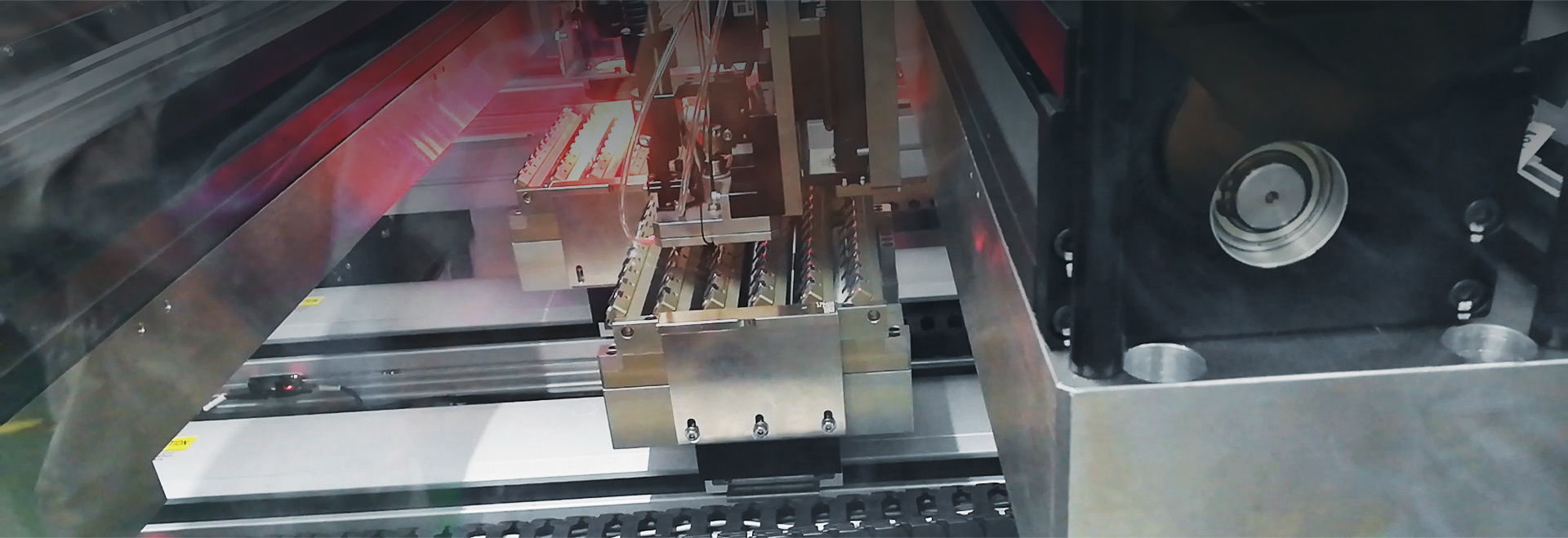

Laser solder ball soldering machine

Features:

1. Suitable for high-precision :±10um

2. Components'min. clearance: 100um

3. Solder ball diameters: 0.1mm -1.8mm

4. Applied to tin, gold, silver coated surface

5. Yield: >99% .

Laser parameters:

1. Power:50-200W(Optional)

2. Wavelength: 1064±5nm

3. Type: CW laser

1.Fluxless.

2.Mask/ Stencil-less

3.Environmental-friendly

4.High precision

5.Low thermal stress

6.3D soldering

Other parameters:

1. Dimension:1m* 1.1m *1.65m(L*W*H)

2. Power supply:AC220V, 15A

3. Fixture size: can be customized

4. Compressed air:0.6MPa

5. Weight:850kg

6. Nitrogen consumption:0.6L/H

7. Power consumption:2kw

8. CCD: 5 mega-pixel; ±5 resolution

9. Mechanical repetitive precision:±0.2mm

10. Control system: PLC+CCD screen

11. Solder ball: 0.1mm-1.8mm

Strengths:

1.Fluxless.

2.Mask/ Stencil-less

3.Environmental-friendly

4.High precision

5.Low thermal stress

6.3D soldering

Application

◆Micro-electronics: High-definition camera module,mobile camera, soft board connection, point soldering, precised sound control device, sensor soldering, etc.

◆Military: high-precision electronic products

◆Other industries: wafer, optoelectronic products,MEMS, sensor production,BGA,HDD (HGA,HSA) , high-precision components, high precision electronic soldering.

Technical Parameters

◆Micro-electronics: High-definition camera module,mobile camera, soft board connection, point soldering, precised sound control device, sensor soldering, etc.

◆Military: high-precision electronic products

◆Other industries: wafer, optoelectronic products,MEMS, sensor production,BGA,HDD (HGA,HSA) , high-precision components, high precision electronic soldering.