Soldering rework oven

Features

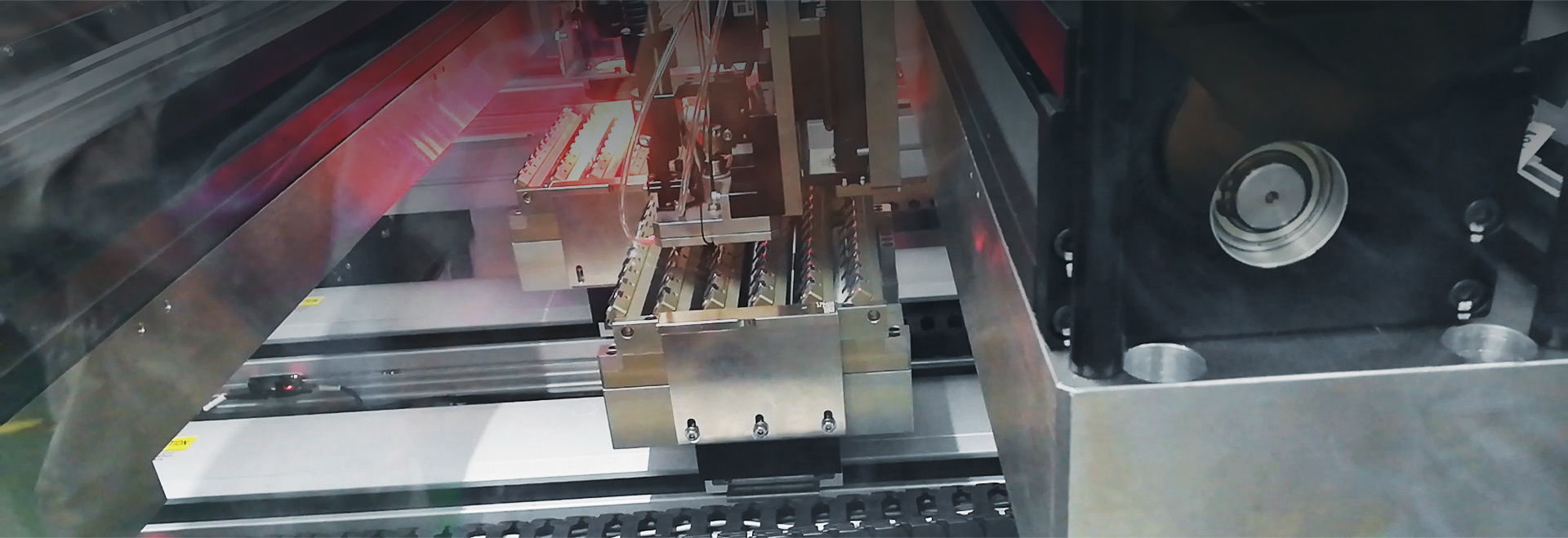

- Remove the components from PCB by micro wave soldering system; easy to remove different types of component by changing the rework head and motor speed

Model USES

- Remove soldered components on the PCB

Soldering rework oven is one of the main products of Shenzhen Anewbest Electronic Technology Co., Ltd. with products with good price and quality.Our factory is a Best suppliers and Manufacturers china,There are also high-quality custom wholesale prices.

A soldering rework oven is a heating equipment used for re-soldering and repairing electronic circuit boards. It provides a controlled preheating environment to reflow solder joints or solder new components onto boards. The rework oven directs hot air through multiple vents and fans to raise the temperature evenly across the circuit board. It has programmable temperature controls and timers for precision heating during the rework process.

Soldering rework requires high heat to melt solder without damaging heat-sensitive components. A rework oven provides a customized heating profile for each board to achieve optimal results. It warms the entire board slowly to minimize thermal shock before focusing heat on specific areas. The oven is equipped with viewing windows and interior lighting for close monitoring during the rework operation.

The temperature range of a typical rework oven is around 75 to 315 degree Celsius. Different temperature presets allow soldering of a wide range of electronic components. The oven has safety features such as overheat protection and emergency stop button to prevent overheating. Proper ventilation and fume extraction system are also installed to remove toxic fumes released from solder flux and PCB laminates at high temperatures.

Soldering rework ovens improve efficiency and quality in PCB repair and remanufacturing. They enable precise control of soldering heat to successfully remove and replace surface mount components without desoldering the entire board. The controlled heating helps minimize damage to nearby components and the PCB base material. The rework ovens also reduce manual soldering errors with automated temperature profiles for each soldering application.

Application

Remove soldered components on the PCB

| Item | Parameter |

| MADOL | ECON- 800 |

| Motor Power | 5KW |

| Power Supply | 220V 50HZ |

| Size of Solder chamber | 110KG |

| Temp of melting solder | Max.300C |

| Time of heating | 60min |

| Dimension | L800*W1 150*H1 800mm |

| Weight | 100KG |

Technical Parameters

Remove soldered components on the PCB

| Item | Parameter |

| MADOL | ECON- 800 |

| Motor Power | 5KW |

| Power Supply | 220V 50HZ |

| Size of Solder chamber | 110KG |

| Temp of melting solder | Max.300C |

| Time of heating | 60min |

| Dimension | L800*W1 150*H1 800mm |

| Weight | 100KG |