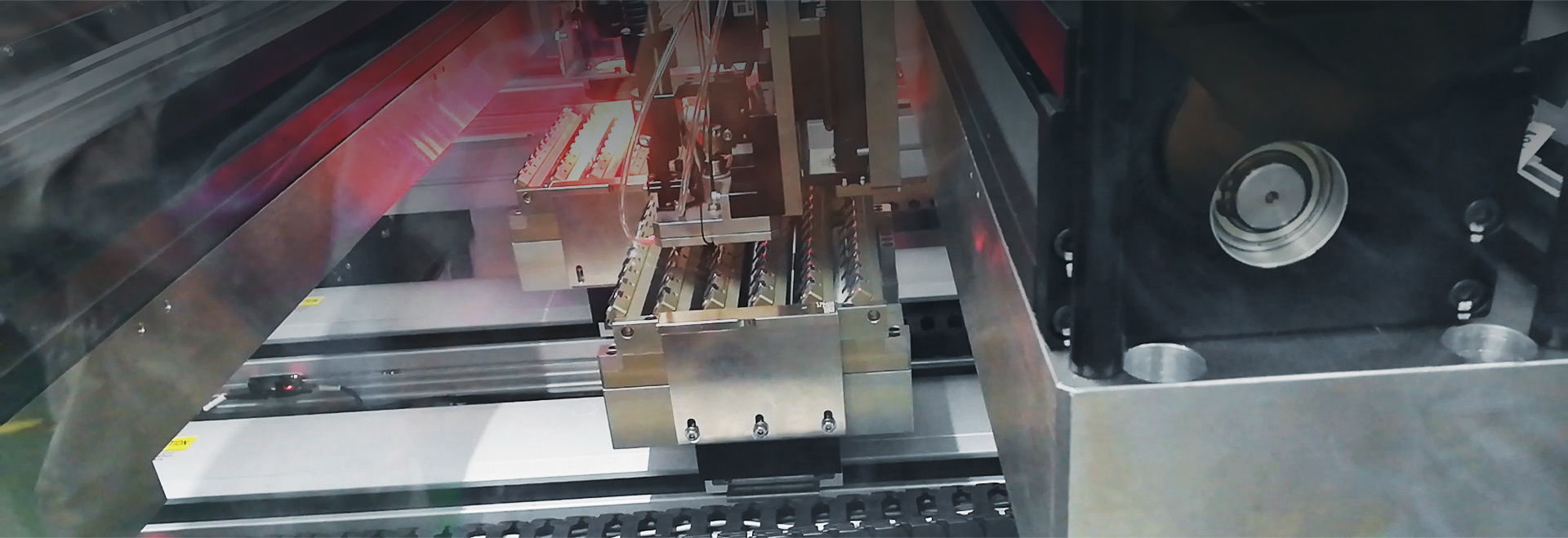

High frequency induction soldering machine

Based on electromagnetic induction heating technology, equipped with three-axis motion platform and temperature control system, this product can realize the welding of thick plate through-hole pin devices, surface mount components, deep buried and other heterostructures. It has wide application range, short welding time and high production efficiency

Introduction

- Based on electromagnetic induction heating technology, equipped with three-axis motion platform and temperature control system, this product can realize the welding of thick plate through-hole pin devices, surface mount components, deep buried and other heterostructures. It has wide application range, short welding time and high production efficiency

Advantages

- With temperature control system, it can control constant temperature welding and output real-time temperature control curve

- The welding time is short, the temperature can be instantly raised to more than 200 ℃, high efficiency and good energy efficiency

- Equipped with three-axis positioning platform to achieve accurate positioning.It has a wide range of applications.

- It can not only weld thick plate pin devices, but also weld surface paste components such as BGA and mini led.

Applicable components:

- Realize the welding of multiple products on one equipment

- Thick plate welding of through-hole elements;

- Welding of surface mounted components;

- Welding of heterogeneous structures such as deep buried holes and sandwich solder joints.

Application

- Realize the welding of multiple products on one equipment

- Thick plate welding of through-hole elements;

- Welding of surface mounted components;

- Welding of heterogeneous structures such as deep buried holes and sandwich solder joints.

| Power | 220V 50Hz |

| supply | 6kW |

| Power consumption | 500KHz-1.1MHz |

| Precision of adjustment | 0.02mm |

| Mode of cooling | Water cooled |

| Vision positioning accuracy | PLC |

| Dimension | 1000×1000×1000mm |

| Weight | 500kg |

Technical Parameters

- Realize the welding of multiple products on one equipment

- Thick plate welding of through-hole elements;

- Welding of surface mounted components;

- Welding of heterogeneous structures such as deep buried holes and sandwich solder joints.

| Power | 220V 50Hz |

| supply | 6kW |

| Power consumption | 500KHz-1.1MHz |

| Precision of adjustment | 0.02mm |

| Mode of cooling | Water cooled |

| Vision positioning accuracy | PLC |

| Dimension | 1000×1000×1000mm |

| Weight | 500kg |