01

2023

-

08

Automating Your Packaging Process: The Essentials of Automatic CCM Module Packaging Lines

Author:

Introduction: In the rapidly evolving world of manufacturing and processing machinery, optimizing production efficiency is crucial for success. Automatic packaging solutions, such as the Automatic CCM module packaging line, have emerged as game-changers in the industry. This article delves into the essential aspects of an Automatic CCM module packaging line, providing valuable insights for profess

Introduction:

In the rapidly evolving world of manufacturing and processing machinery, optimizing production efficiency is crucial for success. Automatic packaging solutions, such as the Automatic CCM module packaging line, have emerged as game-changers in the industry. This article delves into the essential aspects of an Automatic CCM module packaging line, providing valuable insights for professionals in the field.

Key Components of an Automatic CCM Module Packaging Line:

1. Conveyor System: The heart of an Automatic CCM module packaging line is its conveyor system. This system efficiently transports modules from one station to another, ensuring a smooth and continuous packaging process.

2. Automatic Loading and Unloading: These lines feature automatic loading and unloading mechanisms, reducing the need for manual intervention. This streamlines the packaging process, minimizing downtime and enhancing productivity.

3. Module Alignment and Positioning: Precise alignment and positioning of CCM modules play a vital role in ensuring accurate packaging. Automatic CCM module packaging lines utilize advanced sensors and robotics to achieve optimal alignment, reducing errors and enhancing the overall quality of the packaging.

4. Packaging Material Handling: These lines incorporate specialized mechanisms for handling packaging materials, such as trays, boxes, or containers. Whether it's loading the materials or sealing the final package, the Automatic CCM module packaging line offers seamless material handling capabilities.

Benefits of an Automatic CCM Module Packaging Line:

1. Increased Efficiency: By automating the packaging process, an Automatic CCM module packaging line significantly reduces manual labor requirements. This leads to higher production rates, shorter lead times, and improved overall efficiency.

2. Enhanced Accuracy: With advanced alignment and positioning systems, these lines ensure precise and consistent packaging results. This eliminates errors and enhances product quality, reducing the need for rework or returns.

3. Cost Savings: The automated nature of an Automatic CCM module packaging line reduces labor costs associated with manual packaging. Additionally, the higher production rates and decreased errors result in cost savings for manufacturers.

4. Adaptability and Flexibility: These packaging lines offer the flexibility to accommodate various module sizes and packaging requirements. With adjustable settings and customizable options, manufacturers can easily adapt the line to meet specific needs.

Conclusion:

In the realm of manufacturing and processing machinery, the Automatic CCM module packaging line proves to be a transformative solution. By automating the packaging process and incorporating advanced features, this line enhances efficiency, accuracy, and overall productivity. With its numerous benefits and adaptable nature, the Automatic CCM module packaging line is a valuable addition to any packaging production line.

In the rapidly evolving world of manufacturing and processing machinery, optimizing production efficiency is crucial for success. Automatic packaging solutions, such as the Automatic CCM module packaging line, have emerged as game-changers in the industry. This article delves into the essential aspects of an Automatic CCM module packaging line, providing valuable insights for professionals in the field.

Key Components of an Automatic CCM Module Packaging Line:

1. Conveyor System: The heart of an Automatic CCM module packaging line is its conveyor system. This system efficiently transports modules from one station to another, ensuring a smooth and continuous packaging process.

2. Automatic Loading and Unloading: These lines feature automatic loading and unloading mechanisms, reducing the need for manual intervention. This streamlines the packaging process, minimizing downtime and enhancing productivity.

3. Module Alignment and Positioning: Precise alignment and positioning of CCM modules play a vital role in ensuring accurate packaging. Automatic CCM module packaging lines utilize advanced sensors and robotics to achieve optimal alignment, reducing errors and enhancing the overall quality of the packaging.

4. Packaging Material Handling: These lines incorporate specialized mechanisms for handling packaging materials, such as trays, boxes, or containers. Whether it's loading the materials or sealing the final package, the Automatic CCM module packaging line offers seamless material handling capabilities.

Benefits of an Automatic CCM Module Packaging Line:

1. Increased Efficiency: By automating the packaging process, an Automatic CCM module packaging line significantly reduces manual labor requirements. This leads to higher production rates, shorter lead times, and improved overall efficiency.

2. Enhanced Accuracy: With advanced alignment and positioning systems, these lines ensure precise and consistent packaging results. This eliminates errors and enhances product quality, reducing the need for rework or returns.

3. Cost Savings: The automated nature of an Automatic CCM module packaging line reduces labor costs associated with manual packaging. Additionally, the higher production rates and decreased errors result in cost savings for manufacturers.

4. Adaptability and Flexibility: These packaging lines offer the flexibility to accommodate various module sizes and packaging requirements. With adjustable settings and customizable options, manufacturers can easily adapt the line to meet specific needs.

Conclusion:

In the realm of manufacturing and processing machinery, the Automatic CCM module packaging line proves to be a transformative solution. By automating the packaging process and incorporating advanced features, this line enhances efficiency, accuracy, and overall productivity. With its numerous benefits and adaptable nature, the Automatic CCM module packaging line is a valuable addition to any packaging production line.

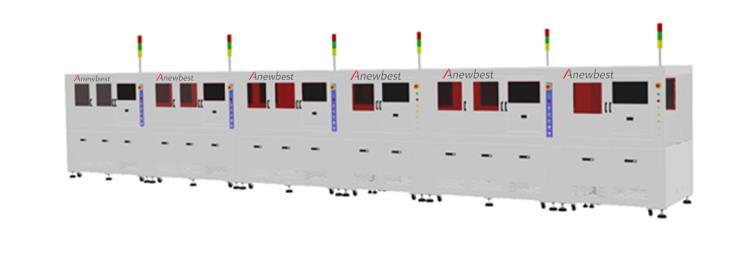

Automatic CCM module packaging line

undefined