02

2023

-

08

Maximize Efficiency and Quality Control with an Automatic CCM Module Packaging Line

Author:

Table of Contents: 1. Introduction: The Power of Automation in Packaging 2. Understanding the Automatic CCM Module Packaging Line 3. Benefits of Implementing an Automatic CCM Module Packaging Line 4. Features and Capabilities of an Automatic CCM Module Packaging Line 5. Key Considerations for Implementing an Automatic CCM Module Packaging Line 6. Frequently Asked Questions (FAQs) 7. Conclusion 1.

Table of Contents:

1. Introduction: The Power of Automation in Packaging

2. Understanding the Automatic CCM Module Packaging Line

3. Benefits of Implementing an Automatic CCM Module Packaging Line

4. Features and Capabilities of an Automatic CCM Module Packaging Line

5. Key Considerations for Implementing an Automatic CCM Module Packaging Line

6. Frequently Asked Questions (FAQs)

7. Conclusion

1. Introduction: The Power of Automation in Packaging

In today's fast-paced manufacturing environment, businesses are constantly looking for ways to maximize efficiency and optimize quality control. One area that holds significant potential for improvement is the packaging process. Automation has emerged as a game-changer, streamlining operations and delivering substantial benefits.

2. Understanding the Automatic CCM Module Packaging Line

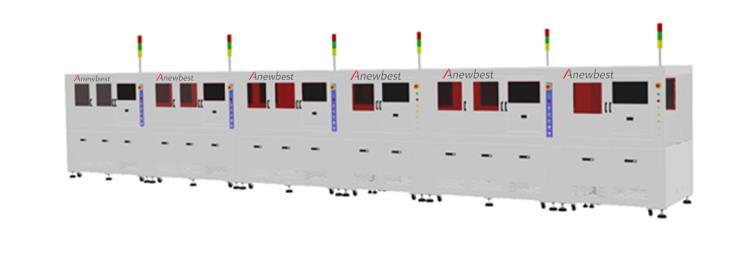

The Automatic CCM Module Packaging Line is a state-of-the-art packaging solution designed to handle the specific requirements of CCM (Continuous Compaction Control) modules. It combines advanced robotics, smart sensors, and intelligent software to automate the entire packaging process. From module placement to sealing and labeling, this cutting-edge system ensures precise and consistent packaging every time.

3. Benefits of Implementing an Automatic CCM Module Packaging Line

Implementing an Automatic CCM Module Packaging Line offers numerous benefits to manufacturers. Firstly, it significantly enhances efficiency by eliminating manual labor and reducing production cycle times. With automation, businesses can achieve higher output rates and meet demanding customer deadlines.

Moreover, this advanced packaging line enhances quality control by minimizing human error and product damage. The precise robotic movements guarantee consistent packaging, reducing the risk of faulty modules reaching customers. By maintaining the highest possible quality standards, businesses can enhance their reputation and gain a competitive edge in the market.

4. Features and Capabilities of an Automatic CCM Module Packaging Line

The Automatic CCM Module Packaging Line boasts several key features and capabilities that contribute to its exceptional performance. It is equipped with cutting-edge robotic arms that can handle multiple modules simultaneously, maximizing throughput. Additionally, the system incorporates intelligent sensors that detect any deviations in the packaging process, ensuring accuracy and preventing errors.

Furthermore, the Automatic CCM Module Packaging Line integrates with existing production systems seamlessly. Its user-friendly interface allows for easy operation and real-time monitoring, enabling operators to analyze data and make informed decisions. This advanced technology also supports customization, accommodating different module sizes and packaging requirements.

5. Key Considerations for Implementing an Automatic CCM Module Packaging Line

Before implementing an Automatic CCM Module Packaging Line, businesses must consider certain factors to ensure a successful integration. Firstly, it is essential to assess the specific needs and production volume to determine the appropriate system configuration. Evaluating the available floor space and potential modifications required is also critical.

Furthermore, comprehensive training and ongoing technical support are vital for maximizing the benefits of this technology. Collaborating with experienced suppliers and manufacturers can provide valuable guidance during the implementation process. Conducting thorough cost-benefit analyses and ROI projections helps justify the investment and evaluate the potential return.

6. Frequently Asked Questions (FAQs)

Q1: What is the typical throughput capacity of an Automatic CCM Module Packaging Line?

A1: The throughput capacity depends on various factors such as module size, packaging requirements, and system configuration. However, these advanced packaging lines can handle high volumes, significantly enhancing production efficiency.

Q2: Can the Automatic CCM Module Packaging Line be customized for different module sizes?

A2: Yes, the system is designed to accommodate various module sizes and packaging requirements. Its flexibility allows businesses to adapt to changing market demands seamlessly.

Q3: How does automation enhance quality control in the packaging process?

A3: Automation eliminates human error and ensures consistent packaging, reducing the risk of faulty modules reaching customers. This leads to improved quality control and enhanced customer satisfaction.

Q4: Can the Automatic CCM Module Packaging Line integrate with existing production systems?

A4: Yes, the system is designed to integrate seamlessly with existing production systems, minimizing disruptions and maximizing efficiency.

Q5: What kind of technical support is available for businesses implementing an Automatic CCM Module Packaging Line?

A5: Reputable suppliers and manufacturers provide comprehensive training and ongoing technical support to ensure smooth implementation and efficient operation.

7. Conclusion

In conclusion, implementing an Automatic CCM Module Packaging Line can revolutionize the packaging process, maximizing efficiency, and ensuring top-notch quality control. This cutting-edge technology offers numerous benefits to manufacturers, including increased throughput, reduced labor costs, and improved customer satisfaction. By embracing automation, businesses can stay ahead of the competition and drive success in today's dynamic market.

1. Introduction: The Power of Automation in Packaging

2. Understanding the Automatic CCM Module Packaging Line

3. Benefits of Implementing an Automatic CCM Module Packaging Line

4. Features and Capabilities of an Automatic CCM Module Packaging Line

5. Key Considerations for Implementing an Automatic CCM Module Packaging Line

6. Frequently Asked Questions (FAQs)

7. Conclusion

1. Introduction: The Power of Automation in Packaging

In today's fast-paced manufacturing environment, businesses are constantly looking for ways to maximize efficiency and optimize quality control. One area that holds significant potential for improvement is the packaging process. Automation has emerged as a game-changer, streamlining operations and delivering substantial benefits.

2. Understanding the Automatic CCM Module Packaging Line

The Automatic CCM Module Packaging Line is a state-of-the-art packaging solution designed to handle the specific requirements of CCM (Continuous Compaction Control) modules. It combines advanced robotics, smart sensors, and intelligent software to automate the entire packaging process. From module placement to sealing and labeling, this cutting-edge system ensures precise and consistent packaging every time.

3. Benefits of Implementing an Automatic CCM Module Packaging Line

Implementing an Automatic CCM Module Packaging Line offers numerous benefits to manufacturers. Firstly, it significantly enhances efficiency by eliminating manual labor and reducing production cycle times. With automation, businesses can achieve higher output rates and meet demanding customer deadlines.

Moreover, this advanced packaging line enhances quality control by minimizing human error and product damage. The precise robotic movements guarantee consistent packaging, reducing the risk of faulty modules reaching customers. By maintaining the highest possible quality standards, businesses can enhance their reputation and gain a competitive edge in the market.

4. Features and Capabilities of an Automatic CCM Module Packaging Line

The Automatic CCM Module Packaging Line boasts several key features and capabilities that contribute to its exceptional performance. It is equipped with cutting-edge robotic arms that can handle multiple modules simultaneously, maximizing throughput. Additionally, the system incorporates intelligent sensors that detect any deviations in the packaging process, ensuring accuracy and preventing errors.

Furthermore, the Automatic CCM Module Packaging Line integrates with existing production systems seamlessly. Its user-friendly interface allows for easy operation and real-time monitoring, enabling operators to analyze data and make informed decisions. This advanced technology also supports customization, accommodating different module sizes and packaging requirements.

5. Key Considerations for Implementing an Automatic CCM Module Packaging Line

Before implementing an Automatic CCM Module Packaging Line, businesses must consider certain factors to ensure a successful integration. Firstly, it is essential to assess the specific needs and production volume to determine the appropriate system configuration. Evaluating the available floor space and potential modifications required is also critical.

Furthermore, comprehensive training and ongoing technical support are vital for maximizing the benefits of this technology. Collaborating with experienced suppliers and manufacturers can provide valuable guidance during the implementation process. Conducting thorough cost-benefit analyses and ROI projections helps justify the investment and evaluate the potential return.

6. Frequently Asked Questions (FAQs)

Q1: What is the typical throughput capacity of an Automatic CCM Module Packaging Line?

A1: The throughput capacity depends on various factors such as module size, packaging requirements, and system configuration. However, these advanced packaging lines can handle high volumes, significantly enhancing production efficiency.

Q2: Can the Automatic CCM Module Packaging Line be customized for different module sizes?

A2: Yes, the system is designed to accommodate various module sizes and packaging requirements. Its flexibility allows businesses to adapt to changing market demands seamlessly.

Q3: How does automation enhance quality control in the packaging process?

A3: Automation eliminates human error and ensures consistent packaging, reducing the risk of faulty modules reaching customers. This leads to improved quality control and enhanced customer satisfaction.

Q4: Can the Automatic CCM Module Packaging Line integrate with existing production systems?

A4: Yes, the system is designed to integrate seamlessly with existing production systems, minimizing disruptions and maximizing efficiency.

Q5: What kind of technical support is available for businesses implementing an Automatic CCM Module Packaging Line?

A5: Reputable suppliers and manufacturers provide comprehensive training and ongoing technical support to ensure smooth implementation and efficient operation.

7. Conclusion

In conclusion, implementing an Automatic CCM Module Packaging Line can revolutionize the packaging process, maximizing efficiency, and ensuring top-notch quality control. This cutting-edge technology offers numerous benefits to manufacturers, including increased throughput, reduced labor costs, and improved customer satisfaction. By embracing automation, businesses can stay ahead of the competition and drive success in today's dynamic market.

Automatic CCM module packaging line

undefined