01

2023

-

08

Streamline Your Packaging Process with an Automatic CCM Module Packaging Line

Author:

Table of Contents: 1. Introduction: The Power of Automation in Packaging 2. Understanding the Automatic CCM Module Packaging Line 3. Advantages of Using an Automatic CCM Module Packaging Line 4. Features and Components of an Automatic CCM Module Packaging Line 5. Factors to Consider When Implementing an Automatic CCM Module Packaging Line 6. Common Questions about Automatic CCM Module Packaging Li

Table of Contents:

1. Introduction: The Power of Automation in Packaging

2. Understanding the Automatic CCM Module Packaging Line

3. Advantages of Using an Automatic CCM Module Packaging Line

4. Features and Components of an Automatic CCM Module Packaging Line

5. Factors to Consider When Implementing an Automatic CCM Module Packaging Line

6. Common Questions about Automatic CCM Module Packaging Lines

7. Conclusion: Embrace Automation for Enhanced Packaging Efficiency

In today's fast-paced business environment, efficiency is crucial to stay competitive. Packaging plays a vital role in delivering products to consumers, and optimizing this process can have a significant impact on overall productivity. The advent of automation has revolutionized various industries, including packaging. By integrating an Automatic CCM Module Packaging Line into your operations, you can streamline your packaging process, reduce labor costs, and enhance overall efficiency.

The Automatic CCM Module Packaging Line is a cutting-edge technology designed to automate the packaging process. It combines various modules, such as carton erecting, product insertion, sealing, and labeling, into a seamless operation. This integrated approach eliminates the need for manual intervention, minimizing errors and increasing output.

Implementing an Automatic CCM Module Packaging Line offers numerous advantages for businesses. Firstly, it significantly improves productivity by automating repetitive tasks, allowing your workforce to focus on higher-value activities. This leads to faster turnaround times and increased output.

Secondly, automation ensures consistency and accuracy in packaging. The precise and reliable nature of the Automatic CCM Module Packaging Line reduces the risk of errors, ensuring that every product is packaged correctly. This consistency enhances product quality and customer satisfaction.

Moreover, automating your packaging process can lead to cost savings. By reducing the need for manual labor, businesses can save on labor costs and minimize human error-related expenses. Additionally, automation allows for better inventory management, reducing the risk of overstocking or stockouts.

The Automatic CCM Module Packaging Line consists of several key components that work together to streamline the packaging process. These include:

- Carton Erector: This module automatically erects cartons, ready for product insertion.

- Product Insertion: The Automatic CCM Module Packaging Line ensures precise and efficient product insertion into cartons, eliminating the need for manual handling.

- Sealing and Taping: The line incorporates sealing and taping mechanisms to securely close cartons, providing a professional and secure packaging solution.

- Labeling: Automatic labeling systems can be integrated into the line, allowing for accurate and consistent product labeling.

- Control System: The line is equipped with a control system that monitors and controls the entire packaging process, ensuring seamless operation.

Before integrating an Automatic CCM Module Packaging Line into your operations, it's important to consider several factors:

- Production Capacity: Assess your production needs and ensure that the line can meet your desired output.

- Compatibility: Ensure that the line is compatible with your existing packaging equipment and processes.

- Space Requirements: Determine the space required for the line and ensure it fits within your facility.

- Maintenance and Support: Consider the availability of maintenance services and technical support for the line.

- Cost and ROI: Evaluate the costs involved in implementing the line and estimate the return on investment based on increased productivity and cost savings.

FAQs:

Q1: How can an Automatic CCM Module Packaging Line improve my packaging process?

Q2: Is the line suitable for packaging various product types and sizes?

Q3: Can the line be customized to meet specific packaging requirements?

Q4: What are the maintenance requirements for an Automatic CCM Module Packaging Line?

Q5: How long does it take to install and set up the line?

In conclusion, integrating an Automatic CCM Module Packaging Line into your packaging process can significantly streamline operations, improve productivity, and enhance product quality. By leveraging the power of automation, businesses can stay ahead in today's competitive market. Consider the advantages, features, and factors associated with this technology and make an informed decision to optimize your packaging process. Embrace automation and unlock the full potential of your packaging operations.

1. Introduction: The Power of Automation in Packaging

2. Understanding the Automatic CCM Module Packaging Line

3. Advantages of Using an Automatic CCM Module Packaging Line

4. Features and Components of an Automatic CCM Module Packaging Line

5. Factors to Consider When Implementing an Automatic CCM Module Packaging Line

6. Common Questions about Automatic CCM Module Packaging Lines

7. Conclusion: Embrace Automation for Enhanced Packaging Efficiency

1. Introduction: The Power of Automation in Packaging

In today's fast-paced business environment, efficiency is crucial to stay competitive. Packaging plays a vital role in delivering products to consumers, and optimizing this process can have a significant impact on overall productivity. The advent of automation has revolutionized various industries, including packaging. By integrating an Automatic CCM Module Packaging Line into your operations, you can streamline your packaging process, reduce labor costs, and enhance overall efficiency.

2. Understanding the Automatic CCM Module Packaging Line

The Automatic CCM Module Packaging Line is a cutting-edge technology designed to automate the packaging process. It combines various modules, such as carton erecting, product insertion, sealing, and labeling, into a seamless operation. This integrated approach eliminates the need for manual intervention, minimizing errors and increasing output.

3. Advantages of Using an Automatic CCM Module Packaging Line

Implementing an Automatic CCM Module Packaging Line offers numerous advantages for businesses. Firstly, it significantly improves productivity by automating repetitive tasks, allowing your workforce to focus on higher-value activities. This leads to faster turnaround times and increased output.

Secondly, automation ensures consistency and accuracy in packaging. The precise and reliable nature of the Automatic CCM Module Packaging Line reduces the risk of errors, ensuring that every product is packaged correctly. This consistency enhances product quality and customer satisfaction.

Moreover, automating your packaging process can lead to cost savings. By reducing the need for manual labor, businesses can save on labor costs and minimize human error-related expenses. Additionally, automation allows for better inventory management, reducing the risk of overstocking or stockouts.

4. Features and Components of an Automatic CCM Module Packaging Line

The Automatic CCM Module Packaging Line consists of several key components that work together to streamline the packaging process. These include:

- Carton Erector: This module automatically erects cartons, ready for product insertion.

- Product Insertion: The Automatic CCM Module Packaging Line ensures precise and efficient product insertion into cartons, eliminating the need for manual handling.

- Sealing and Taping: The line incorporates sealing and taping mechanisms to securely close cartons, providing a professional and secure packaging solution.

- Labeling: Automatic labeling systems can be integrated into the line, allowing for accurate and consistent product labeling.

- Control System: The line is equipped with a control system that monitors and controls the entire packaging process, ensuring seamless operation.

5. Factors to Consider When Implementing an Automatic CCM Module Packaging Line

Before integrating an Automatic CCM Module Packaging Line into your operations, it's important to consider several factors:

- Production Capacity: Assess your production needs and ensure that the line can meet your desired output.

- Compatibility: Ensure that the line is compatible with your existing packaging equipment and processes.

- Space Requirements: Determine the space required for the line and ensure it fits within your facility.

- Maintenance and Support: Consider the availability of maintenance services and technical support for the line.

- Cost and ROI: Evaluate the costs involved in implementing the line and estimate the return on investment based on increased productivity and cost savings.

6. Common Questions about Automatic CCM Module Packaging Lines

FAQs:

Q1: How can an Automatic CCM Module Packaging Line improve my packaging process?

Q2: Is the line suitable for packaging various product types and sizes?

Q3: Can the line be customized to meet specific packaging requirements?

Q4: What are the maintenance requirements for an Automatic CCM Module Packaging Line?

Q5: How long does it take to install and set up the line?

7. Conclusion: Embrace Automation for Enhanced Packaging Efficiency

In conclusion, integrating an Automatic CCM Module Packaging Line into your packaging process can significantly streamline operations, improve productivity, and enhance product quality. By leveraging the power of automation, businesses can stay ahead in today's competitive market. Consider the advantages, features, and factors associated with this technology and make an informed decision to optimize your packaging process. Embrace automation and unlock the full potential of your packaging operations.

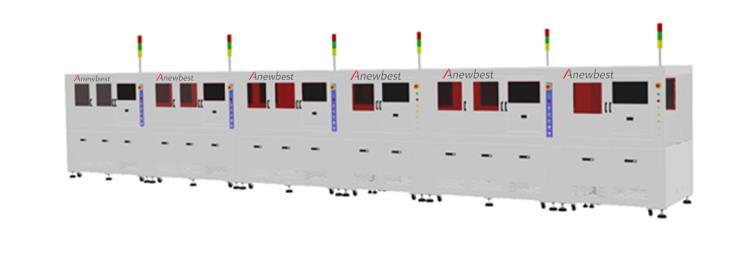

Automatic CCM module packaging line

undefined