08

2023

-

10

Laser Plastic Welding Machine: Revolutionizing Automotive Repair and Tools

Author:

Introduction: The automotive industry is constantly evolving, and so are the technologies used in automotive repair and maintenance. One such groundbreaking innovation is the laser plastic welding machine. This advanced tool has revolutionized the way professionals work with welding equipment and tools in the automotive repair sector. In this article, we will explore the concept of a laser plastic

Introduction:

The automotive industry is constantly evolving, and so are the technologies used in automotive repair and maintenance. One such groundbreaking innovation is the laser plastic welding machine. This advanced tool has revolutionized the way professionals work with welding equipment and tools in the automotive repair sector. In this article, we will explore the concept of a laser plastic welding machine and its significance in the automotive industry.

1. Understanding Laser Plastic Welding:

Laser plastic welding is a technique that uses laser energy to join plastic components together. Unlike traditional welding methods, it does not rely on heat transfer through direct contact. Instead, a laser beam is focused on the interface between the plastic parts, creating localized heat that melts the plastic and forms a strong bond. This precision welding process ensures minimal damage to the surrounding areas, making it an ideal choice for automotive repairs.

2. Advantages of Laser Plastic Welding:

Laser plastic welding machines offer several advantages over conventional welding techniques. Here are some key benefits:

a. Enhanced Precision: The focused laser beam enables precise control over the welding process, resulting in clean and accurate welds. This level of precision is crucial in automotive repair, where quality and aesthetics play a significant role.

b. Versatility: Laser plastic welding machines can join various types of plastics, including dissimilar materials. This versatility allows automotive professionals to repair components made from different plastic compositions, expanding their capabilities and reducing the need for replacements.

c. Time and Cost Efficiency: Laser plastic welding is a fast and efficient process. It eliminates the need for additional materials such as adhesives or fasteners, reducing repair time and costs. Moreover, the ability to repair rather than replace damaged components helps save money in the long run.

d. Non-Destructive Welding: Laser plastic welding produces minimal thermal stress, ensuring that the surrounding areas remain intact. This non-destructive nature of the process avoids potential damage to sensitive automotive parts, making it a reliable choice for repairs.

3. Applications in the Automotive Industry:

Laser plastic welding machines find extensive applications in the automotive industry. Some notable examples include:

a. Bumper Repair: Bumpers often require repairs due to minor collisions. Laser plastic welding provides an efficient and seamless solution, enabling professionals to restore the bumper's integrity without compromising its appearance.

b. Interior Component Repairs: From dashboards to door panels, various interior components can be effectively repaired using laser plastic welding. This technique ensures a strong bond while preserving the original design and finish.

c. Headlight Restoration: Laser plastic welding machines can also repair cracked or damaged headlight housings. By restoring the structural integrity of the housing, the machine helps maintain the functionality and aesthetics of the headlights.

In conclusion, laser plastic welding machines have revolutionized the automotive repair industry by offering precise, versatile, and efficient solutions for professionals working with automotive welding equipment and tools. The ability to repair components rather than replacing them not only saves time and money but also contributes to sustainable practices. As the automotive industry continues to advance, the adoption of laser plastic welding machines is expected to grow, further transforming the way professionals approach automotive repairs and maintenance.

The automotive industry is constantly evolving, and so are the technologies used in automotive repair and maintenance. One such groundbreaking innovation is the laser plastic welding machine. This advanced tool has revolutionized the way professionals work with welding equipment and tools in the automotive repair sector. In this article, we will explore the concept of a laser plastic welding machine and its significance in the automotive industry.

1. Understanding Laser Plastic Welding:

Laser plastic welding is a technique that uses laser energy to join plastic components together. Unlike traditional welding methods, it does not rely on heat transfer through direct contact. Instead, a laser beam is focused on the interface between the plastic parts, creating localized heat that melts the plastic and forms a strong bond. This precision welding process ensures minimal damage to the surrounding areas, making it an ideal choice for automotive repairs.

2. Advantages of Laser Plastic Welding:

Laser plastic welding machines offer several advantages over conventional welding techniques. Here are some key benefits:

a. Enhanced Precision: The focused laser beam enables precise control over the welding process, resulting in clean and accurate welds. This level of precision is crucial in automotive repair, where quality and aesthetics play a significant role.

b. Versatility: Laser plastic welding machines can join various types of plastics, including dissimilar materials. This versatility allows automotive professionals to repair components made from different plastic compositions, expanding their capabilities and reducing the need for replacements.

c. Time and Cost Efficiency: Laser plastic welding is a fast and efficient process. It eliminates the need for additional materials such as adhesives or fasteners, reducing repair time and costs. Moreover, the ability to repair rather than replace damaged components helps save money in the long run.

d. Non-Destructive Welding: Laser plastic welding produces minimal thermal stress, ensuring that the surrounding areas remain intact. This non-destructive nature of the process avoids potential damage to sensitive automotive parts, making it a reliable choice for repairs.

3. Applications in the Automotive Industry:

Laser plastic welding machines find extensive applications in the automotive industry. Some notable examples include:

a. Bumper Repair: Bumpers often require repairs due to minor collisions. Laser plastic welding provides an efficient and seamless solution, enabling professionals to restore the bumper's integrity without compromising its appearance.

b. Interior Component Repairs: From dashboards to door panels, various interior components can be effectively repaired using laser plastic welding. This technique ensures a strong bond while preserving the original design and finish.

c. Headlight Restoration: Laser plastic welding machines can also repair cracked or damaged headlight housings. By restoring the structural integrity of the housing, the machine helps maintain the functionality and aesthetics of the headlights.

In conclusion, laser plastic welding machines have revolutionized the automotive repair industry by offering precise, versatile, and efficient solutions for professionals working with automotive welding equipment and tools. The ability to repair components rather than replacing them not only saves time and money but also contributes to sustainable practices. As the automotive industry continues to advance, the adoption of laser plastic welding machines is expected to grow, further transforming the way professionals approach automotive repairs and maintenance.

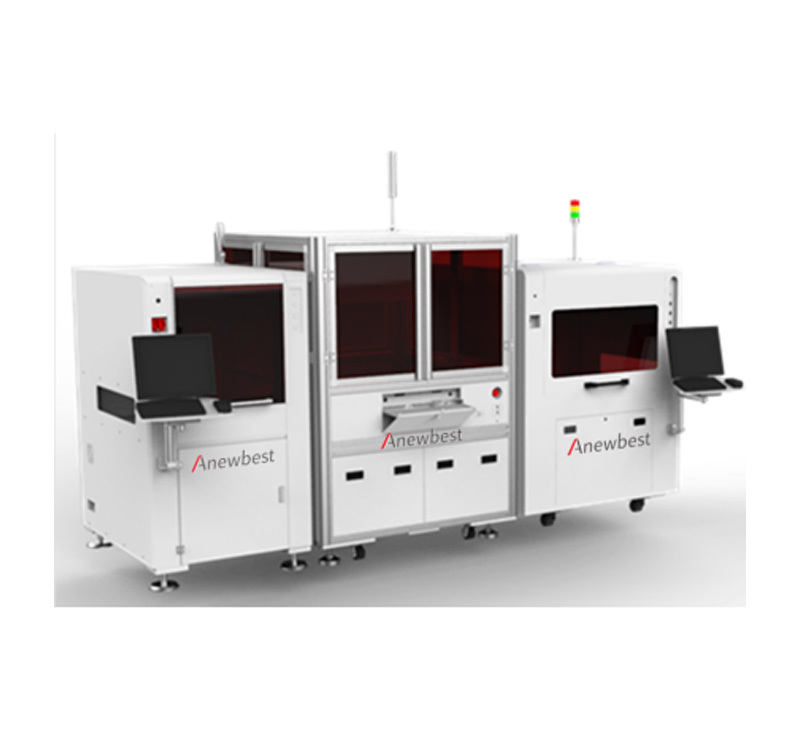

laser plastic welding machine

undefined