07

2023

-

10

Optimizing Automotive Repair: Innovations in Laser Plastic Welding Machines

Author:

Table of Contents: 1. Introduction: The Evolution of Automotive Repair 2. Understanding Laser Plastic Welding 3. Advantages of Laser Plastic Welding Machines 4. Applications in Automotive Repair 5. Innovations in Laser Plastic Welding Machines 6. Future Prospects and Trends 7. Frequently Asked Questions (FAQs) 8. Conclusion 1. Introduction: The Evolution of Automotive Repair As automotive repair h

Table of Contents:

1. Introduction: The Evolution of Automotive Repair

2. Understanding Laser Plastic Welding

3. Advantages of Laser Plastic Welding Machines

4. Applications in Automotive Repair

5. Innovations in Laser Plastic Welding Machines

6. Future Prospects and Trends

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction: The Evolution of Automotive Repair

As automotive repair has progressed over the years, new technologies have emerged to enhance the efficiency and quality of repairs. Laser plastic welding machines have become a game-changer in the industry, offering precise, reliable, and durable repair solutions.

2. Understanding Laser Plastic Welding

Laser plastic welding is a non-contact welding technique that utilizes laser energy to join plastic components. It involves the use of a laser beam to heat and melt the plastic material, creating a strong bond. This process is highly precise and produces minimal heat-affected zones, minimizing the risk of damage to surrounding areas.

3. Advantages of Laser Plastic Welding Machines

Laser plastic welding machines offer numerous advantages over traditional welding methods. These machines provide:

- High precision: Laser technology allows for precise control over the welding process, ensuring accurate and consistent results.

- Strength and durability: Laser-welded joints exhibit excellent strength and durability, making them ideal for automotive repair applications.

- Aesthetically pleasing repairs: The precise nature of laser plastic welding enables seamless and nearly invisible repairs, enhancing the overall appearance of the vehicle.

- Time and cost savings: Laser plastic welding machines offer faster welding speeds and require minimal post-processing, reducing repair time and costs.

4. Applications in Automotive Repair

Laser plastic welding machines find extensive applications in automotive repair. Some common applications include:

- Bumper repair: Laser welding can effectively repair cracked or damaged bumpers, restoring their structural integrity.

- Headlight repair: Damaged headlight housings can be repaired using laser plastic welding, ensuring proper functionality and appearance.

- Interior component repair: Laser welding can be used for repairing various interior components, such as door panels, consoles, and dashboard parts.

- Sensor and electronic component repair: Laser plastic welding enables precise repairs to sensors and electronic components, ensuring their proper functioning.

5. Innovations in Laser Plastic Welding Machines

The continuous advancements in laser plastic welding machines have revolutionized automotive repair. Some notable innovations include:

- Multi-beam technology: Modern laser plastic welding machines employ multi-beam technology, allowing for simultaneous welding of multiple spots, enhancing efficiency and productivity.

- Real-time process monitoring: Advanced machines feature integrated sensors and monitoring systems that provide real-time feedback on the welding process, ensuring optimal results.

- Intelligent control systems: AI-powered control systems analyze the welding parameters and adjust them in real-time, optimizing the welding process for maximum strength and quality.

- Automated systems: Robotic arms and automated systems have been integrated into laser plastic welding machines, improving precision and reducing human error.

6. Future Prospects and Trends

The future of laser plastic welding machines in automotive repair looks promising. Some anticipated trends include:

- Integration with augmented reality: Laser plastic welding machines may incorporate augmented reality technology, providing technicians with interactive visual guidance during the repair process.

- Enhanced material compatibility: Ongoing research aims to expand the range of plastic materials that can be effectively welded using laser technology, opening up new possibilities for automotive repair.

- Miniaturization and portability: Manufacturers are working on developing compact and portable laser plastic welding machines, enabling on-site repairs and reducing dependence on larger equipment.

7. Frequently Asked Questions (FAQs)

FAQ 1: How does laser plastic welding differ from traditional welding methods?

FAQ 2: Are laser-welded joints as strong as conventionally welded joints?

FAQ 3: Can laser plastic welding be used for repairing metal components?

FAQ 4: What are the safety considerations when using laser plastic welding machines?

FAQ 5: Will laser plastic welding machines replace traditional welding methods in automotive repair?

8. Conclusion

In conclusion, laser plastic welding machines have emerged as a game-changing technology in the automotive repair industry. Their precision, strength, and aesthetic appeal make them a preferred choice for repairing various plastic components. With continuous innovations and promising future prospects, laser plastic welding machines are set to revolutionize the way automotive repairs are conducted, ensuring efficient, reliable, and visually pleasing results.

1. Introduction: The Evolution of Automotive Repair

2. Understanding Laser Plastic Welding

3. Advantages of Laser Plastic Welding Machines

4. Applications in Automotive Repair

5. Innovations in Laser Plastic Welding Machines

6. Future Prospects and Trends

7. Frequently Asked Questions (FAQs)

8. Conclusion

1. Introduction: The Evolution of Automotive Repair

As automotive repair has progressed over the years, new technologies have emerged to enhance the efficiency and quality of repairs. Laser plastic welding machines have become a game-changer in the industry, offering precise, reliable, and durable repair solutions.

2. Understanding Laser Plastic Welding

Laser plastic welding is a non-contact welding technique that utilizes laser energy to join plastic components. It involves the use of a laser beam to heat and melt the plastic material, creating a strong bond. This process is highly precise and produces minimal heat-affected zones, minimizing the risk of damage to surrounding areas.

3. Advantages of Laser Plastic Welding Machines

Laser plastic welding machines offer numerous advantages over traditional welding methods. These machines provide:

- High precision: Laser technology allows for precise control over the welding process, ensuring accurate and consistent results.

- Strength and durability: Laser-welded joints exhibit excellent strength and durability, making them ideal for automotive repair applications.

- Aesthetically pleasing repairs: The precise nature of laser plastic welding enables seamless and nearly invisible repairs, enhancing the overall appearance of the vehicle.

- Time and cost savings: Laser plastic welding machines offer faster welding speeds and require minimal post-processing, reducing repair time and costs.

4. Applications in Automotive Repair

Laser plastic welding machines find extensive applications in automotive repair. Some common applications include:

- Bumper repair: Laser welding can effectively repair cracked or damaged bumpers, restoring their structural integrity.

- Headlight repair: Damaged headlight housings can be repaired using laser plastic welding, ensuring proper functionality and appearance.

- Interior component repair: Laser welding can be used for repairing various interior components, such as door panels, consoles, and dashboard parts.

- Sensor and electronic component repair: Laser plastic welding enables precise repairs to sensors and electronic components, ensuring their proper functioning.

5. Innovations in Laser Plastic Welding Machines

The continuous advancements in laser plastic welding machines have revolutionized automotive repair. Some notable innovations include:

- Multi-beam technology: Modern laser plastic welding machines employ multi-beam technology, allowing for simultaneous welding of multiple spots, enhancing efficiency and productivity.

- Real-time process monitoring: Advanced machines feature integrated sensors and monitoring systems that provide real-time feedback on the welding process, ensuring optimal results.

- Intelligent control systems: AI-powered control systems analyze the welding parameters and adjust them in real-time, optimizing the welding process for maximum strength and quality.

- Automated systems: Robotic arms and automated systems have been integrated into laser plastic welding machines, improving precision and reducing human error.

6. Future Prospects and Trends

The future of laser plastic welding machines in automotive repair looks promising. Some anticipated trends include:

- Integration with augmented reality: Laser plastic welding machines may incorporate augmented reality technology, providing technicians with interactive visual guidance during the repair process.

- Enhanced material compatibility: Ongoing research aims to expand the range of plastic materials that can be effectively welded using laser technology, opening up new possibilities for automotive repair.

- Miniaturization and portability: Manufacturers are working on developing compact and portable laser plastic welding machines, enabling on-site repairs and reducing dependence on larger equipment.

7. Frequently Asked Questions (FAQs)

FAQ 1: How does laser plastic welding differ from traditional welding methods?

FAQ 2: Are laser-welded joints as strong as conventionally welded joints?

FAQ 3: Can laser plastic welding be used for repairing metal components?

FAQ 4: What are the safety considerations when using laser plastic welding machines?

FAQ 5: Will laser plastic welding machines replace traditional welding methods in automotive repair?

8. Conclusion

In conclusion, laser plastic welding machines have emerged as a game-changing technology in the automotive repair industry. Their precision, strength, and aesthetic appeal make them a preferred choice for repairing various plastic components. With continuous innovations and promising future prospects, laser plastic welding machines are set to revolutionize the way automotive repairs are conducted, ensuring efficient, reliable, and visually pleasing results.

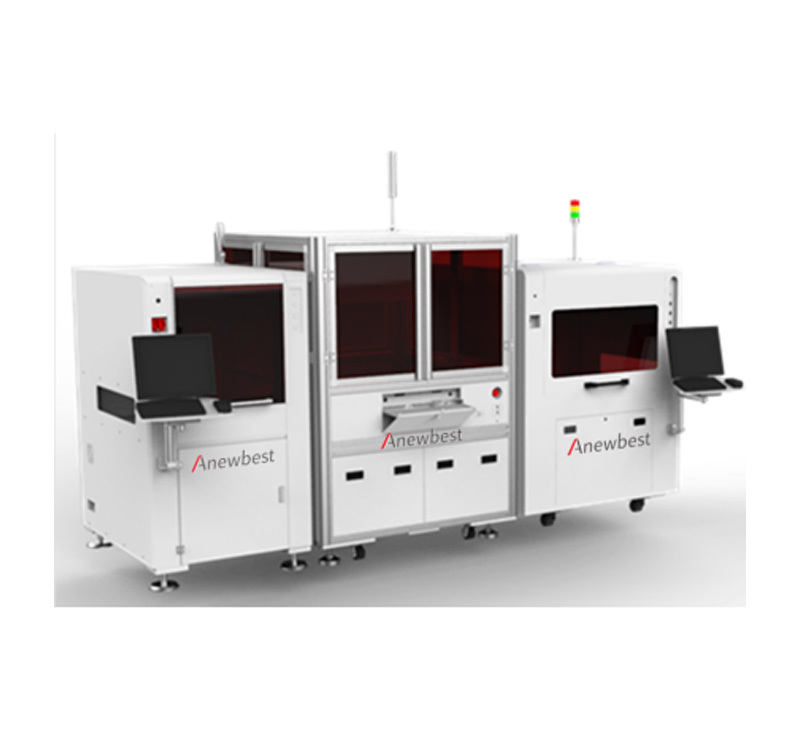

laser plastic welding machine

undefined