22

2023

-

09

Understanding How a High Effective Automatic Dross Recovery Machine Works

Author:

Table of Contents: 1. Introduction: The Need for Efficient Dross Management 2. What is a High Effective Automatic Dross Recovery Machine? 3. Key Components of a Dross Recovery Machine 3.1. Dross Inlet System 3.2. Heating System 3.3. Separation System 3.4. Cooling System 3.5. Discharge System 4. Understanding the Working Mechanism 4.1. Step 1: Dross Inlet 4.2. Step 2: Heating

Table of Contents:

1. Introduction: The Need for Efficient Dross Management

2. What is a High Effective Automatic Dross Recovery Machine?

3. Key Components of a Dross Recovery Machine

3.1. Dross Inlet System

3.2. Heating System

3.3. Separation System

3.4. Cooling System

3.5. Discharge System

4. Understanding the Working Mechanism

4.1. Step 1: Dross Inlet

4.2. Step 2: Heating

4.3. Step 3: Separation

4.4. Step 4: Cooling

4.5. Step 5: Discharge

5. Advantages of a High Effective Automatic Dross Recovery Machine

6. Frequently Asked Questions (FAQs)

6.1. How does a dross recovery machine increase efficiency?

6.2. Can the machine handle different types of dross?

6.3. Is it easy to operate and maintain?

6.4. What are the energy requirements for the machine?

6.5. Can it be customized to fit different production capacities?

7. Conclusion

1. Introduction: The Need for Efficient Dross Management

Managing dross, a byproduct of various industrial processes, is a critical challenge faced by many industries. Improper disposal of dross not only leads to environmental concerns but also results in significant material and financial losses. In this article, we delve into the workings of a high effective automatic dross recovery machine, an innovative solution that ensures efficient dross management.

2. What is a High Effective Automatic Dross Recovery Machine?

A high effective automatic dross recovery machine is a technologically advanced equipment designed to extract valuable metal from dross and separate it from the waste material. By employing a combination of heating, separation, and cooling processes, this machine efficiently recovers usable metal, minimizing waste and maximizing productivity.

3. Key Components of a Dross Recovery Machine

To understand how a high effective automatic dross recovery machine works, let's explore its key components:

3.1. Dross Inlet System

The dross inlet system is responsible for feeding the dross into the machine. It ensures a continuous supply of dross to facilitate a seamless recovery process.

3.2. Heating System

The heating system plays a crucial role in the dross recovery process. It subjects the dross to controlled heat, which causes the metal components to melt and separate from the impurities.

3.3. Separation System

Once the dross is heated, the separation system comes into action. It uses various mechanisms such as centrifugal force or gravity to separate the molten metal from the non-metallic impurities. This process ensures a high recovery rate of pure metal.

3.4. Cooling System

After the separation process, the cooling system rapidly cools the recovered metal, causing it to solidify. This ensures the metal can be easily handled and further processed.

3.5. Discharge System

The discharge system is responsible for collecting the separated metal and transferring it to a designated container or conveyor belt for further processing or storage.

4. Understanding the Working Mechanism

Let's now dive into the step-by-step working mechanism of a high effective automatic dross recovery machine:

4.1. Step 1: Dross Inlet

The dross is fed into the machine through the dross inlet system. The machine is designed to handle various forms of dross, including skimmings, slag, or powders.

4.2. Step 2: Heating

Once inside the machine, the dross is subjected to controlled heat using a heating system. The precise temperature and duration of heating depend on the type of dross being processed. The heat melts the metal components within the dross, separating them from the impurities.

4.3. Step 3: Separation

The molten metal is then separated from the non-metallic impurities using the separation system. This may involve centrifugal force, gravity, or other separation techniques. The separated metal is collected, while the impurities are directed towards the waste outlet.

4.4. Step 4: Cooling

The separated metal is rapidly cooled using a cooling system. This ensures the metal solidifies quickly, making it easier to handle and transport for further processing.

4.5. Step 5: Discharge

In the final step, the recovered metal is discharged into a designated container or onto a conveyor belt, ready for subsequent processing or storage.

5. Advantages of a High Effective Automatic Dross Recovery Machine

Investing in a high effective automatic dross recovery machine offers numerous benefits, including:

- Significantly reduced waste and material loss

- Increased production efficiency and cost savings

- Improved environmental sustainability

- High recovery rate of pure metal

- Easy operation and maintenance

- Customizability to fit different production capacities

6. Frequently Asked Questions (FAQs)

6.1. How does a dross recovery machine increase efficiency?

A dross recovery machine increases efficiency by extracting valuable metal from dross, minimizing waste, and reducing the need for manual labor-intensive separation processes.

6.2. Can the machine handle different types of dross?

Yes, a high effective automatic dross recovery machine is designed to handle various types of dross, including skimmings, slag, and powders.

6.3. Is it easy to operate and maintain?

Yes, these machines are designed with user-friendly interfaces and require minimal maintenance. Regular cleaning and inspection ensure optimal performance.

6.4. What are the energy requirements for the machine?

The energy requirements vary depending on the size and capacity of the machine. However, modern dross recovery machines are designed to be energy-efficient, optimizing power consumption.

6.5. Can it be customized to fit different production capacities?

Yes, manufacturers offer dross recovery machines in various sizes and capacities. They can be customized to meet specific production requirements.

7. Conclusion

A high effective automatic dross recovery machine is a game-changer in the field of dross management. By harnessing advanced technology, these machines efficiently recover valuable metal from dross, improving productivity, sustainability, and cost-effectiveness. Investing in such a machine can revolutionize your dross management process, ensuring maximum recovery and minimal waste.

1. Introduction: The Need for Efficient Dross Management

2. What is a High Effective Automatic Dross Recovery Machine?

3. Key Components of a Dross Recovery Machine

3.1. Dross Inlet System

3.2. Heating System

3.3. Separation System

3.4. Cooling System

3.5. Discharge System

4. Understanding the Working Mechanism

4.1. Step 1: Dross Inlet

4.2. Step 2: Heating

4.3. Step 3: Separation

4.4. Step 4: Cooling

4.5. Step 5: Discharge

5. Advantages of a High Effective Automatic Dross Recovery Machine

6. Frequently Asked Questions (FAQs)

6.1. How does a dross recovery machine increase efficiency?

6.2. Can the machine handle different types of dross?

6.3. Is it easy to operate and maintain?

6.4. What are the energy requirements for the machine?

6.5. Can it be customized to fit different production capacities?

7. Conclusion

1. Introduction: The Need for Efficient Dross Management

Managing dross, a byproduct of various industrial processes, is a critical challenge faced by many industries. Improper disposal of dross not only leads to environmental concerns but also results in significant material and financial losses. In this article, we delve into the workings of a high effective automatic dross recovery machine, an innovative solution that ensures efficient dross management.

2. What is a High Effective Automatic Dross Recovery Machine?

A high effective automatic dross recovery machine is a technologically advanced equipment designed to extract valuable metal from dross and separate it from the waste material. By employing a combination of heating, separation, and cooling processes, this machine efficiently recovers usable metal, minimizing waste and maximizing productivity.

3. Key Components of a Dross Recovery Machine

To understand how a high effective automatic dross recovery machine works, let's explore its key components:

3.1. Dross Inlet System

The dross inlet system is responsible for feeding the dross into the machine. It ensures a continuous supply of dross to facilitate a seamless recovery process.

3.2. Heating System

The heating system plays a crucial role in the dross recovery process. It subjects the dross to controlled heat, which causes the metal components to melt and separate from the impurities.

3.3. Separation System

Once the dross is heated, the separation system comes into action. It uses various mechanisms such as centrifugal force or gravity to separate the molten metal from the non-metallic impurities. This process ensures a high recovery rate of pure metal.

3.4. Cooling System

After the separation process, the cooling system rapidly cools the recovered metal, causing it to solidify. This ensures the metal can be easily handled and further processed.

3.5. Discharge System

The discharge system is responsible for collecting the separated metal and transferring it to a designated container or conveyor belt for further processing or storage.

4. Understanding the Working Mechanism

Let's now dive into the step-by-step working mechanism of a high effective automatic dross recovery machine:

4.1. Step 1: Dross Inlet

The dross is fed into the machine through the dross inlet system. The machine is designed to handle various forms of dross, including skimmings, slag, or powders.

4.2. Step 2: Heating

Once inside the machine, the dross is subjected to controlled heat using a heating system. The precise temperature and duration of heating depend on the type of dross being processed. The heat melts the metal components within the dross, separating them from the impurities.

4.3. Step 3: Separation

The molten metal is then separated from the non-metallic impurities using the separation system. This may involve centrifugal force, gravity, or other separation techniques. The separated metal is collected, while the impurities are directed towards the waste outlet.

4.4. Step 4: Cooling

The separated metal is rapidly cooled using a cooling system. This ensures the metal solidifies quickly, making it easier to handle and transport for further processing.

4.5. Step 5: Discharge

In the final step, the recovered metal is discharged into a designated container or onto a conveyor belt, ready for subsequent processing or storage.

5. Advantages of a High Effective Automatic Dross Recovery Machine

Investing in a high effective automatic dross recovery machine offers numerous benefits, including:

- Significantly reduced waste and material loss

- Increased production efficiency and cost savings

- Improved environmental sustainability

- High recovery rate of pure metal

- Easy operation and maintenance

- Customizability to fit different production capacities

6. Frequently Asked Questions (FAQs)

6.1. How does a dross recovery machine increase efficiency?

A dross recovery machine increases efficiency by extracting valuable metal from dross, minimizing waste, and reducing the need for manual labor-intensive separation processes.

6.2. Can the machine handle different types of dross?

Yes, a high effective automatic dross recovery machine is designed to handle various types of dross, including skimmings, slag, and powders.

6.3. Is it easy to operate and maintain?

Yes, these machines are designed with user-friendly interfaces and require minimal maintenance. Regular cleaning and inspection ensure optimal performance.

6.4. What are the energy requirements for the machine?

The energy requirements vary depending on the size and capacity of the machine. However, modern dross recovery machines are designed to be energy-efficient, optimizing power consumption.

6.5. Can it be customized to fit different production capacities?

Yes, manufacturers offer dross recovery machines in various sizes and capacities. They can be customized to meet specific production requirements.

7. Conclusion

A high effective automatic dross recovery machine is a game-changer in the field of dross management. By harnessing advanced technology, these machines efficiently recover valuable metal from dross, improving productivity, sustainability, and cost-effectiveness. Investing in such a machine can revolutionize your dross management process, ensuring maximum recovery and minimal waste.

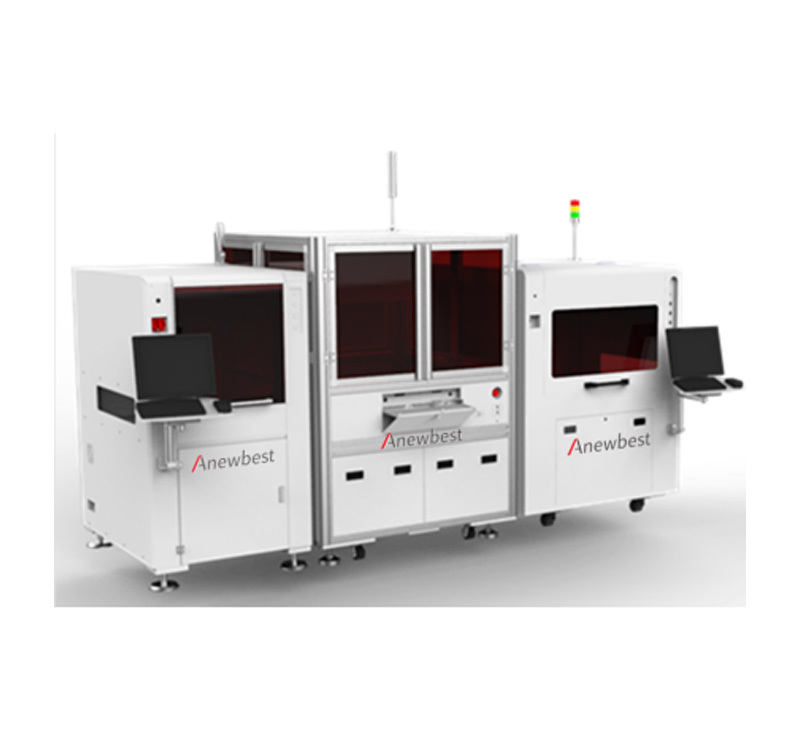

High effective automatic dross recovery machine

undefined