21

2023

-

09

Highly Effective Automatic Dross Recovery Machine: Revolutionizing the Welding Industry

Author:

Title: Revolutionizing the Welding Industry: The Power of a Highly Effective Automatic Dross Recovery Machine Introduction: In the ever-evolving field of electrical engineering and welding, staying updated with the latest equipment is crucial for professionals seeking efficiency and productivity. One such groundbreaking invention that has revolutionized the industry is the highly effective automat

Title: Revolutionizing the Welding Industry: The Power of a Highly Effective Automatic Dross Recovery Machine

Introduction:

In the ever-evolving field of electrical engineering and welding, staying updated with the latest equipment is crucial for professionals seeking efficiency and productivity. One such groundbreaking invention that has revolutionized the industry is the highly effective automatic dross recovery machine. This article explores the features and advantages of this innovative solution and sheds light on its applications in the electrical and welding sector.

The Importance of Dross Recovery:

Dross, a byproduct of welding processes, refers to the solidified impurities that accumulate on the surface of molten metal. It not only compromises the quality of welds but also hampers the overall efficiency of the welding process. Traditional methods of dross removal are time-consuming and require manual labor. However, with the advent of the highly effective automatic dross recovery machine, this challenge is being overcome with unprecedented ease and efficiency.

Unveiling the Automatic Dross Recovery Machine:

The automatic dross recovery machine is a cutting-edge piece of equipment that automates the process of dross removal. Powered by advanced technology, it efficiently separates impurities from the molten metal, ensuring the production of high-quality welds. This automated solution eliminates the need for manual intervention, saving time and increasing productivity in the welding industry.

Benefits and Applications:

1. Enhancing Efficiency: The automatic dross recovery machine significantly reduces the downtime associated with manual dross removal. Its high-speed processing capabilities allow for continuous operation, leading to enhanced efficiency in welding processes.

2. Improving Weld Quality: By effectively removing dross, this machine ensures clean and flawless welds, improving their strength and durability. The absence of impurities results in a higher-quality end product, meeting industry standards and customer expectations.

3. Cost Savings: With the automatic dross recovery machine, businesses can achieve substantial cost savings. By reducing manual labor and minimizing material wastage, companies can optimize their resources and improve their bottom line.

4. Versatile Applications: This innovative solution finds applications in various welding processes, including MIG, TIG, and arc welding. Its adaptability across different welding techniques makes it a valuable asset for professionals in the electrical and welding sector.

Conclusion:

The highly effective automatic dross recovery machine has emerged as a game-changer in the electrical and welding industry. Its automated dross removal capabilities enable professionals to achieve high-quality welds, enhance efficiency, and reduce costs. By investing in this cutting-edge equipment, businesses can stay ahead of the competition and deliver exceptional results. Embrace the power of technology and unlock the limitless possibilities offered by the automatic dross recovery machine.

Introduction:

In the ever-evolving field of electrical engineering and welding, staying updated with the latest equipment is crucial for professionals seeking efficiency and productivity. One such groundbreaking invention that has revolutionized the industry is the highly effective automatic dross recovery machine. This article explores the features and advantages of this innovative solution and sheds light on its applications in the electrical and welding sector.

The Importance of Dross Recovery:

Dross, a byproduct of welding processes, refers to the solidified impurities that accumulate on the surface of molten metal. It not only compromises the quality of welds but also hampers the overall efficiency of the welding process. Traditional methods of dross removal are time-consuming and require manual labor. However, with the advent of the highly effective automatic dross recovery machine, this challenge is being overcome with unprecedented ease and efficiency.

Unveiling the Automatic Dross Recovery Machine:

The automatic dross recovery machine is a cutting-edge piece of equipment that automates the process of dross removal. Powered by advanced technology, it efficiently separates impurities from the molten metal, ensuring the production of high-quality welds. This automated solution eliminates the need for manual intervention, saving time and increasing productivity in the welding industry.

Benefits and Applications:

1. Enhancing Efficiency: The automatic dross recovery machine significantly reduces the downtime associated with manual dross removal. Its high-speed processing capabilities allow for continuous operation, leading to enhanced efficiency in welding processes.

2. Improving Weld Quality: By effectively removing dross, this machine ensures clean and flawless welds, improving their strength and durability. The absence of impurities results in a higher-quality end product, meeting industry standards and customer expectations.

3. Cost Savings: With the automatic dross recovery machine, businesses can achieve substantial cost savings. By reducing manual labor and minimizing material wastage, companies can optimize their resources and improve their bottom line.

4. Versatile Applications: This innovative solution finds applications in various welding processes, including MIG, TIG, and arc welding. Its adaptability across different welding techniques makes it a valuable asset for professionals in the electrical and welding sector.

Conclusion:

The highly effective automatic dross recovery machine has emerged as a game-changer in the electrical and welding industry. Its automated dross removal capabilities enable professionals to achieve high-quality welds, enhance efficiency, and reduce costs. By investing in this cutting-edge equipment, businesses can stay ahead of the competition and deliver exceptional results. Embrace the power of technology and unlock the limitless possibilities offered by the automatic dross recovery machine.

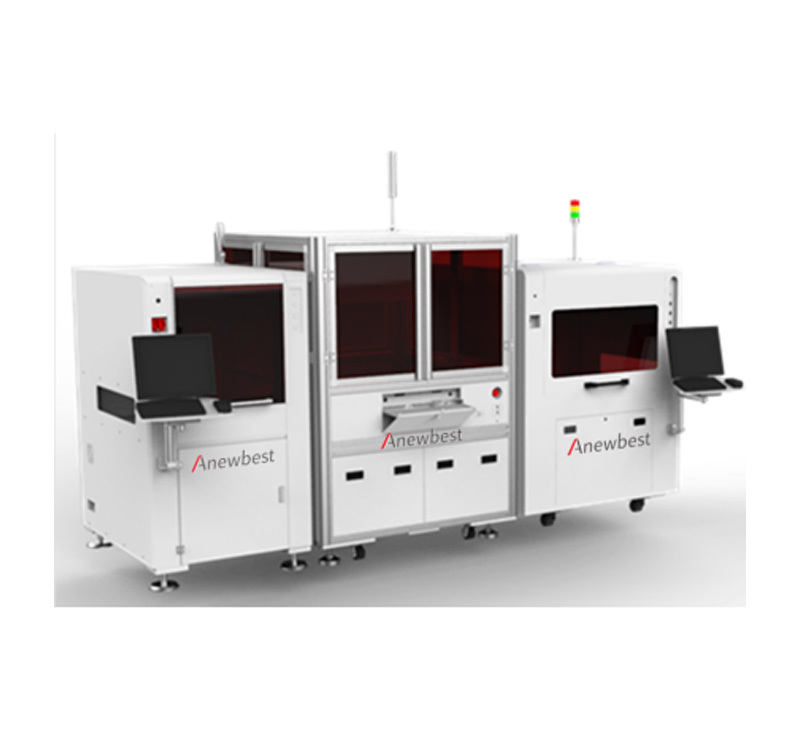

High effective automatic dross recovery machine

undefined