30

2023

-

08

Improving Product Aesthetics Using Laser Plastic Welding Techniques

Author:

Table of Contents: 1. Introduction 2. Understanding Laser Plastic Welding 3. Benefits of Laser Plastic Welding for Product Aesthetics 4. Applications of Laser Plastic Welding in Automotive Industry 5. Enhancing Aesthetics in Consumer Electronics through Laser Plastic Welding 6. Laser Plastic Welding in Medical Device Manufacturing 7. Achieving Flawless Joining with Laser Plastic Welding 8. Overcom

Table of Contents:

1. Introduction

2. Understanding Laser Plastic Welding

3. Benefits of Laser Plastic Welding for Product Aesthetics

4. Applications of Laser Plastic Welding in Automotive Industry

5. Enhancing Aesthetics in Consumer Electronics through Laser Plastic Welding

6. Laser Plastic Welding in Medical Device Manufacturing

7. Achieving Flawless Joining with Laser Plastic Welding

8. Overcoming Design Challenges with Laser Plastic Welding

9. Frequently Asked Questions (FAQs)

a. What is laser plastic welding?

b. How does laser plastic welding improve product aesthetics?

c. Which industries can benefit from laser plastic welding?

d. Are there any limitations to using laser plastic welding?

e. What factors should be considered when implementing laser plastic welding for aesthetics?

10. Conclusion

**1. Introduction**

In today's highly competitive market, product aesthetics play a crucial role in attracting customers and driving sales. To meet the growing demand for visually appealing products, manufacturers are turning to advanced techniques such as laser plastic welding. This article explores how laser plastic welding can enhance product aesthetics and elevate your manufacturing process.

**2. Understanding Laser Plastic Welding**

Laser plastic welding is a precise and efficient method of joining thermoplastic materials using laser energy. It involves melting and fusing the plastics together, creating a seamless bond without the need for additional adhesives or fasteners. This technique allows manufacturers to achieve highly aesthetic and structurally sound products.

**3. Benefits of Laser Plastic Welding for Product Aesthetics**

Laser plastic welding offers several advantages when it comes to improving product aesthetics. Firstly, it enables the creation of clean, invisible weld seams, eliminating any visible marks or distortions. This seamless appearance enhances the overall visual appeal of the product, giving it a high-quality and professional finish.

Additionally, laser plastic welding allows for precise control over the welding process, resulting in consistent and accurate welds. Manufacturers can achieve intricate designs and complex shapes without compromising the product's aesthetics. The technology also offers excellent repeatability, ensuring uniformity across multiple production runs.

**4. Applications of Laser Plastic Welding in Automotive Industry**

The automotive industry has greatly benefited from laser plastic welding in terms of product aesthetics. This technique is extensively used to join various plastic components, such as bumpers, interior trims, and exterior body panels. Laser plastic welding enables car manufacturers to achieve flawless and seamless designs, enhancing the overall look and feel of their vehicles.

**5. Enhancing Aesthetics in Consumer Electronics through Laser Plastic Welding**

Consumer electronics, including smartphones, tablets, and laptops, rely on laser plastic welding to achieve sleek and sophisticated designs. This technique allows for seamless integration of different components, such as display screens, frames, and casings. By eliminating visible seams and gaps, laser plastic welding enhances the aesthetics of consumer electronic devices, elevating their appeal to consumers.

**6. Laser Plastic Welding in Medical Device Manufacturing**

In the medical device industry, laser plastic welding plays a vital role in improving product aesthetics. Medical devices often require precise and hygienic designs, and laser plastic welding enables manufacturers to meet these requirements. From surgical instruments to diagnostic equipment, this technology ensures smooth surfaces, eliminating any potential areas for bacterial growth and enhancing the overall aesthetics of medical devices.

**7. Achieving Flawless Joining with Laser Plastic Welding**

The key to achieving flawless joining with laser plastic welding lies in carefully selecting the appropriate parameters for the materials being welded. Factors such as laser power, beam diameter, welding speed, and joint design play a crucial role in the outcome of the welding process. By optimizing these parameters, manufacturers can achieve consistent and aesthetically pleasing welds.

**8. Overcoming Design Challenges with Laser Plastic Welding**

While laser plastic welding offers numerous benefits for product aesthetics, it also presents certain design challenges. One such challenge is the design of joint geometry, as it determines the strength and appearance of the weld. Manufacturers must carefully consider the design of the joint to ensure it meets both functional and aesthetic requirements. Advanced software simulations can help optimize joint designs for the best aesthetic outcome.

**9. Frequently Asked Questions (FAQs)**

a. What is laser plastic welding?

Laser plastic welding is a technique that uses laser energy to join thermoplastic materials by melting and fusing them together, without the need for adhesives or fasteners.

b. How does laser plastic welding improve product aesthetics?

Laser plastic welding creates clean and invisible weld seams, enhancing the overall visual appeal of the product. It allows for precise control over the welding process, resulting in consistent and accurate welds.

c. Which industries can benefit from laser plastic welding?

Industries such as automotive, consumer electronics, and medical device manufacturing can greatly benefit from laser plastic welding for improved product aesthetics.

d. Are there any limitations to using laser plastic welding?

Laser plastic welding may have limitations on certain materials or joint designs. It is important to consider the specific requirements of each application and consult with experts to determine the feasibility of laser plastic welding.

e. What factors should be considered when implementing laser plastic welding for aesthetics?

Factors such as material compatibility, joint design, laser parameters, and production volume should be taken into account when implementing laser plastic welding for enhanced product aesthetics.

**10. Conclusion**

In conclusion, laser plastic welding is a powerful technique that can significantly improve the aesthetics of products across various industries. From automotive to consumer electronics and medical devices, this innovative technology offers manufacturers the ability to create seamless and visually appealing designs. By harnessing the capabilities of laser plastic welding, you can elevate your product aesthetics and gain a competitive edge in the market.

1. Introduction

2. Understanding Laser Plastic Welding

3. Benefits of Laser Plastic Welding for Product Aesthetics

4. Applications of Laser Plastic Welding in Automotive Industry

5. Enhancing Aesthetics in Consumer Electronics through Laser Plastic Welding

6. Laser Plastic Welding in Medical Device Manufacturing

7. Achieving Flawless Joining with Laser Plastic Welding

8. Overcoming Design Challenges with Laser Plastic Welding

9. Frequently Asked Questions (FAQs)

a. What is laser plastic welding?

b. How does laser plastic welding improve product aesthetics?

c. Which industries can benefit from laser plastic welding?

d. Are there any limitations to using laser plastic welding?

e. What factors should be considered when implementing laser plastic welding for aesthetics?

10. Conclusion

**1. Introduction**

In today's highly competitive market, product aesthetics play a crucial role in attracting customers and driving sales. To meet the growing demand for visually appealing products, manufacturers are turning to advanced techniques such as laser plastic welding. This article explores how laser plastic welding can enhance product aesthetics and elevate your manufacturing process.

**2. Understanding Laser Plastic Welding**

Laser plastic welding is a precise and efficient method of joining thermoplastic materials using laser energy. It involves melting and fusing the plastics together, creating a seamless bond without the need for additional adhesives or fasteners. This technique allows manufacturers to achieve highly aesthetic and structurally sound products.

**3. Benefits of Laser Plastic Welding for Product Aesthetics**

Laser plastic welding offers several advantages when it comes to improving product aesthetics. Firstly, it enables the creation of clean, invisible weld seams, eliminating any visible marks or distortions. This seamless appearance enhances the overall visual appeal of the product, giving it a high-quality and professional finish.

Additionally, laser plastic welding allows for precise control over the welding process, resulting in consistent and accurate welds. Manufacturers can achieve intricate designs and complex shapes without compromising the product's aesthetics. The technology also offers excellent repeatability, ensuring uniformity across multiple production runs.

**4. Applications of Laser Plastic Welding in Automotive Industry**

The automotive industry has greatly benefited from laser plastic welding in terms of product aesthetics. This technique is extensively used to join various plastic components, such as bumpers, interior trims, and exterior body panels. Laser plastic welding enables car manufacturers to achieve flawless and seamless designs, enhancing the overall look and feel of their vehicles.

**5. Enhancing Aesthetics in Consumer Electronics through Laser Plastic Welding**

Consumer electronics, including smartphones, tablets, and laptops, rely on laser plastic welding to achieve sleek and sophisticated designs. This technique allows for seamless integration of different components, such as display screens, frames, and casings. By eliminating visible seams and gaps, laser plastic welding enhances the aesthetics of consumer electronic devices, elevating their appeal to consumers.

**6. Laser Plastic Welding in Medical Device Manufacturing**

In the medical device industry, laser plastic welding plays a vital role in improving product aesthetics. Medical devices often require precise and hygienic designs, and laser plastic welding enables manufacturers to meet these requirements. From surgical instruments to diagnostic equipment, this technology ensures smooth surfaces, eliminating any potential areas for bacterial growth and enhancing the overall aesthetics of medical devices.

**7. Achieving Flawless Joining with Laser Plastic Welding**

The key to achieving flawless joining with laser plastic welding lies in carefully selecting the appropriate parameters for the materials being welded. Factors such as laser power, beam diameter, welding speed, and joint design play a crucial role in the outcome of the welding process. By optimizing these parameters, manufacturers can achieve consistent and aesthetically pleasing welds.

**8. Overcoming Design Challenges with Laser Plastic Welding**

While laser plastic welding offers numerous benefits for product aesthetics, it also presents certain design challenges. One such challenge is the design of joint geometry, as it determines the strength and appearance of the weld. Manufacturers must carefully consider the design of the joint to ensure it meets both functional and aesthetic requirements. Advanced software simulations can help optimize joint designs for the best aesthetic outcome.

**9. Frequently Asked Questions (FAQs)**

a. What is laser plastic welding?

Laser plastic welding is a technique that uses laser energy to join thermoplastic materials by melting and fusing them together, without the need for adhesives or fasteners.

b. How does laser plastic welding improve product aesthetics?

Laser plastic welding creates clean and invisible weld seams, enhancing the overall visual appeal of the product. It allows for precise control over the welding process, resulting in consistent and accurate welds.

c. Which industries can benefit from laser plastic welding?

Industries such as automotive, consumer electronics, and medical device manufacturing can greatly benefit from laser plastic welding for improved product aesthetics.

d. Are there any limitations to using laser plastic welding?

Laser plastic welding may have limitations on certain materials or joint designs. It is important to consider the specific requirements of each application and consult with experts to determine the feasibility of laser plastic welding.

e. What factors should be considered when implementing laser plastic welding for aesthetics?

Factors such as material compatibility, joint design, laser parameters, and production volume should be taken into account when implementing laser plastic welding for enhanced product aesthetics.

**10. Conclusion**

In conclusion, laser plastic welding is a powerful technique that can significantly improve the aesthetics of products across various industries. From automotive to consumer electronics and medical devices, this innovative technology offers manufacturers the ability to create seamless and visually appealing designs. By harnessing the capabilities of laser plastic welding, you can elevate your product aesthetics and gain a competitive edge in the market.

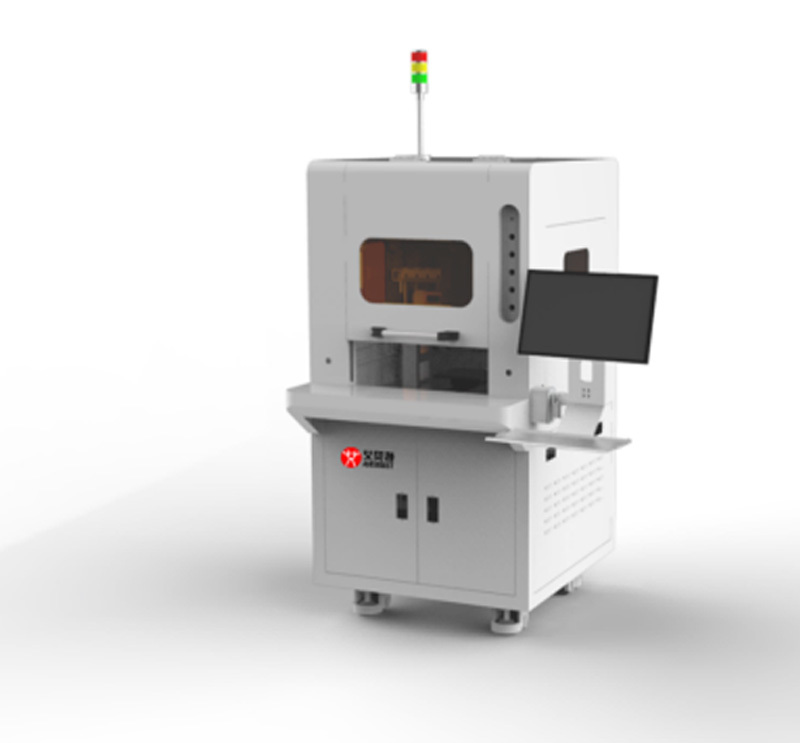

Laser plastic welding machine

undefined