30

2023

-

08

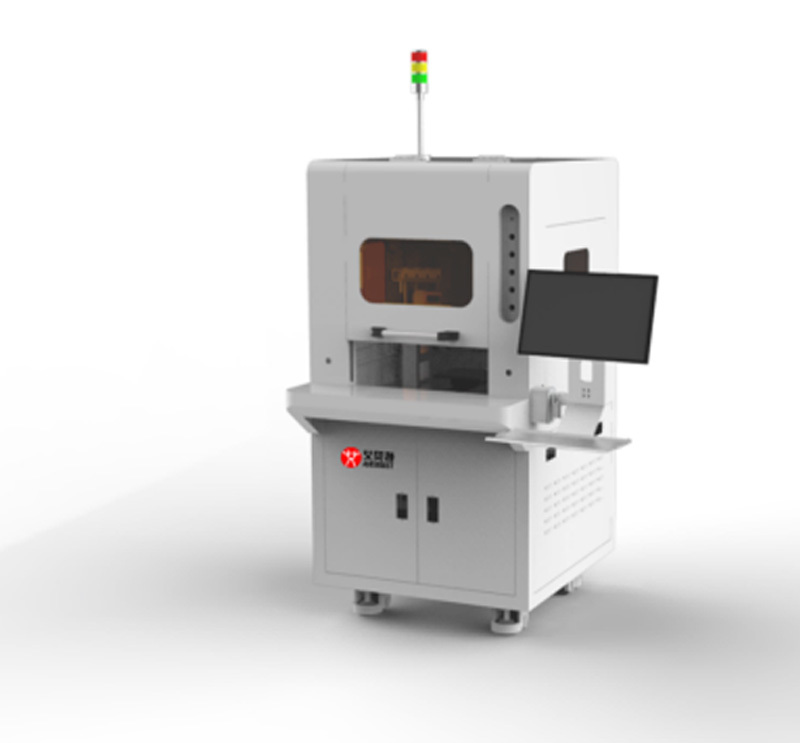

Introduction to Laser Plastic Welding Machines: A Revolutionary Industrial Equipment

Author:

Laser plastic welding machines have revolutionized the welding and cutting processes in various industrial sectors. They offer numerous advantages over traditional welding methods, making them an indispensable tool in the realm of industrial equipment and components. Laser plastic welding machines utilize high-energy laser beams to join or cut plastic components effectively. These machines are equ

Laser plastic welding machines have revolutionized the welding and cutting processes in various industrial sectors. They offer numerous advantages over traditional welding methods, making them an indispensable tool in the realm of industrial equipment and components.

Laser plastic welding machines utilize high-energy laser beams to join or cut plastic components effectively. These machines are equipped with precise laser systems that generate heat to melt and fuse plastics together, creating strong and durable connections. The laser beam is focused on the welding area, providing pinpoint accuracy and control during the process.

Laser plastic welding machines offer several key benefits, making them highly sought after in the industrial sector. Firstly, this technology allows for non-contact welding, eliminating the need for additional materials such as adhesives or solvents. This feature ensures a clean and environmentally friendly welding process.

Secondly, laser plastic welding machines are versatile and can join a wide range of plastic materials, including those with different melting points. This flexibility enables manufacturers to work with various plastic components, expanding their design possibilities.

Furthermore, the laser welding process is highly precise and repeatable. It ensures consistent weld quality, reducing the chances of defects or weak joints. The non-contact nature of laser welding also minimizes the risk of damaging delicate or sensitive components.

Laser plastic welding machines find applications across various industries that rely on precise and reliable welding or cutting processes. In the automotive industry, these machines are used for joining interior and exterior plastic components, such as bumpers, dashboards, and taillights. They provide strong and aesthetically pleasing welds, ensuring the durability and visual appeal of the final products.

The medical industry also benefits from laser plastic welding machines. They are utilized in the manufacturing of medical devices and equipment, such as syringes, catheters, and surgical instruments. The precision and cleanliness of laser welding make it ideal for ensuring sterile and safe medical products.

Additionally, laser plastic welding machines play a crucial role in the electronics industry. They are employed for joining plastic components in electronic devices like smartphones, laptops, and tablets. The non-contact process avoids any damage to sensitive electronic parts, ensuring the integrity and functionality of the final products.

Laser plastic welding machines have transformed the welding and cutting processes in the industrial equipment and component industry. Their ability to provide precise, non-contact welding with various plastic materials offers numerous advantages. From automotive to medical and electronics industries, these machines have become an essential tool for creating strong and durable connections in a wide range of applications. Embrace the power of laser plastic welding machines and unlock endless possibilities in your manufacturing processes.

Laser plastic welding machines utilize high-energy laser beams to join or cut plastic components effectively. These machines are equipped with precise laser systems that generate heat to melt and fuse plastics together, creating strong and durable connections. The laser beam is focused on the welding area, providing pinpoint accuracy and control during the process.

Laser plastic welding machines offer several key benefits, making them highly sought after in the industrial sector. Firstly, this technology allows for non-contact welding, eliminating the need for additional materials such as adhesives or solvents. This feature ensures a clean and environmentally friendly welding process.

Secondly, laser plastic welding machines are versatile and can join a wide range of plastic materials, including those with different melting points. This flexibility enables manufacturers to work with various plastic components, expanding their design possibilities.

Furthermore, the laser welding process is highly precise and repeatable. It ensures consistent weld quality, reducing the chances of defects or weak joints. The non-contact nature of laser welding also minimizes the risk of damaging delicate or sensitive components.

Laser plastic welding machines find applications across various industries that rely on precise and reliable welding or cutting processes. In the automotive industry, these machines are used for joining interior and exterior plastic components, such as bumpers, dashboards, and taillights. They provide strong and aesthetically pleasing welds, ensuring the durability and visual appeal of the final products.

The medical industry also benefits from laser plastic welding machines. They are utilized in the manufacturing of medical devices and equipment, such as syringes, catheters, and surgical instruments. The precision and cleanliness of laser welding make it ideal for ensuring sterile and safe medical products.

Additionally, laser plastic welding machines play a crucial role in the electronics industry. They are employed for joining plastic components in electronic devices like smartphones, laptops, and tablets. The non-contact process avoids any damage to sensitive electronic parts, ensuring the integrity and functionality of the final products.

Laser plastic welding machines have transformed the welding and cutting processes in the industrial equipment and component industry. Their ability to provide precise, non-contact welding with various plastic materials offers numerous advantages. From automotive to medical and electronics industries, these machines have become an essential tool for creating strong and durable connections in a wide range of applications. Embrace the power of laser plastic welding machines and unlock endless possibilities in your manufacturing processes.

Laser plastic welding machine

undefined