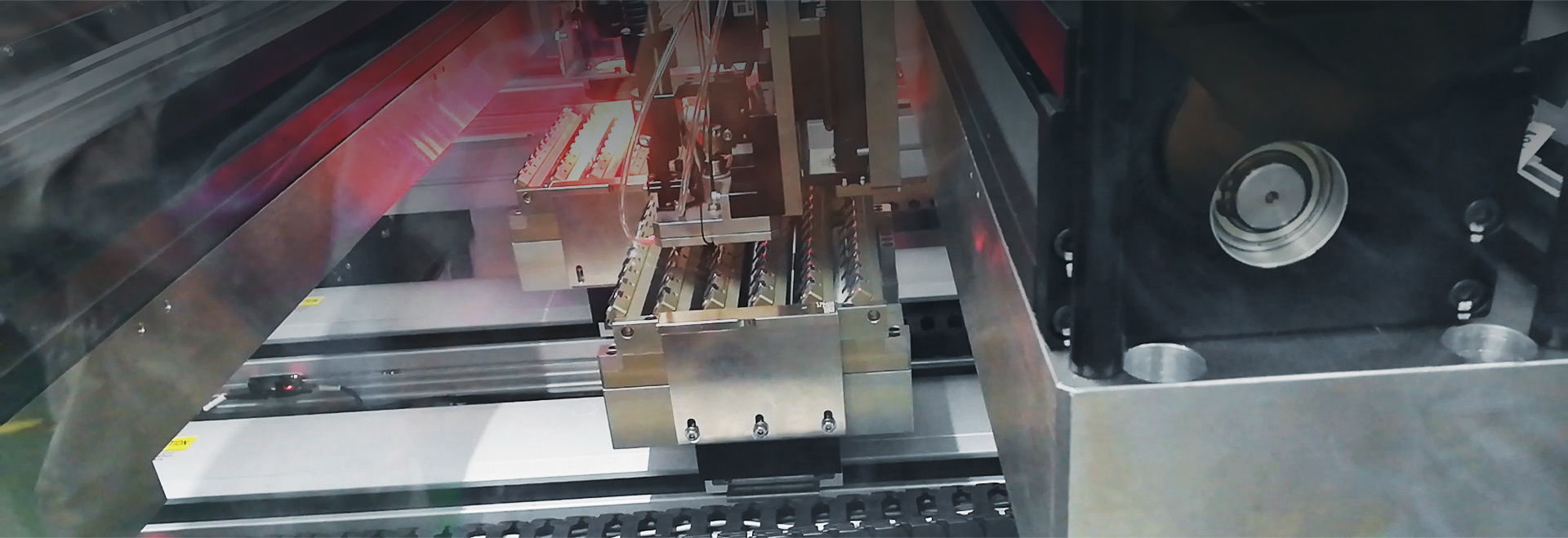

Laser solder wire soldering machine

Introduction

- This product is suitable for PCB spot soldering, metal and non-metal material soldering, plastic welding, sintering, heating and automation of special soldering process on automatic production line. Due to the characteristics of real-time and highprecision control of the temperature of the object, it is especially suitable for high-precision soldering process of parts that cannot withstand high temperature and thermal components around the soldering point.

Machine Advantage

- Constant temperature feedback system, the high-precision infrared temperature detector is used for real-time temperature feedback and control, the solder joint temperature is constant, and the temperature setting is input directly; Solder joint temperature 100-600 ℃ continuously adjustable; Accurate temperature control, error < 3 ℃;

- CCD vision positioning system

- Dynamically observe the soldering process and present the spot clearly in real time; Visual positioning to meet the requirements of fully automatic or unified accelerator work of high-precision devices and reduce manual intervention;

- Coaxial motion system

- Laser, CCD, temperature measurement and indicator light are coaxial at four points to avoid complex optical light adjustment and effectively improve soldering efficiency;

- Modular design

- Tin wire / solder paste is integrated with laser soldering for easy control;

Applicable component type

- It is mainly applicable to the soldering of tht plug-in devices, special-shaped devices and micro precision special parts;

- Suitable for VCM motor coil soldering, FPC or PCB soldering, high-precision LCD soldering and other fields.

- Widely used in mobile phones, aerospace, medical, automotive electronics and other industries

Application

1. Automotive electronics, micro speakers, motors, connectors, cameras, PTH, PGAs (pin grid type electronic devices), RFI connectors, etc.

2. Soldering materials: PCB and pin parts, PCB and wire harness, FPC and pin parts, PCB pin welding, etc.

3、Widely used in cell phones, aerospace, medical, automotive electronics and other industries.

1. Power supply: AC220V±10V

2. Power frequency: 50/60Hz

3. Power consumption: 1KW

4. Laser: 80w-200w(optional)

5. Laser wavelength: 915nm

6. Solder wire diameter: 0.2-1.2mm

7. Minimal solder paste diameter: 0.3mm

8. Positioning: CCD

9. Fiber core diameter: Std.400um

10. Weight: 500kg

11. Dimension: 1.15*1.05*1.75m(L*W*H)

Technical Parameters

1. Automotive electronics, micro speakers, motors, connectors, cameras, PTH, PGAs (pin grid type electronic devices), RFI connectors, etc.

2. Soldering materials: PCB and pin parts, PCB and wire harness, FPC and pin parts, PCB pin welding, etc.

3、Widely used in cell phones, aerospace, medical, automotive electronics and other industries.

1. Power supply: AC220V±10V

2. Power frequency: 50/60Hz

3. Power consumption: 1KW

4. Laser: 80w-200w(optional)

5. Laser wavelength: 915nm

6. Solder wire diameter: 0.2-1.2mm

7. Minimal solder paste diameter: 0.3mm

8. Positioning: CCD

9. Fiber core diameter: Std.400um

10. Weight: 500kg

11. Dimension: 1.15*1.05*1.75m(L*W*H)