11

2023

-

12

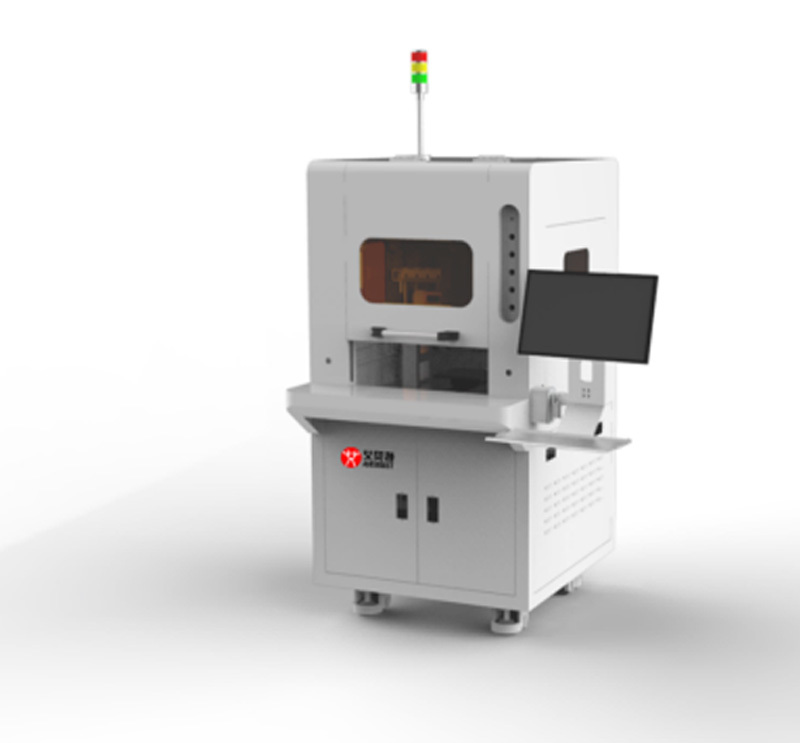

Gold Removal and Re-Tinning Oven Machine: An Essential Tool for the Electrical Heating Equipment Industry

Author:

Introduction: In the realm of electrical heating equipment, the gold removal and re-tinning oven machine plays a crucial role in optimizing performance and extending the longevity of various devices. This article explores the significance of this innovative tool and its applications within the industry. Discover how this advanced technology can benefit your electrical heating equipment and elevate

Introduction:

In the realm of electrical heating equipment, the gold removal and re-tinning oven machine plays a crucial role in optimizing performance and extending the longevity of various devices. This article explores the significance of this innovative tool and its applications within the industry. Discover how this advanced technology can benefit your electrical heating equipment and elevate your operations to new heights.

1. Enhanced Efficiency:

The gold removal and re-tinning oven machine are designed to remove gold plating from various components, ensuring optimal conductivity and enhancing overall efficiency. By eliminating the gold layer, the machine facilitates a more effective flow of electricity, reducing energy losses and improving the performance of electrical heating devices. With this technology, you can unlock greater efficiency and maximize your equipment's output.

2. Prolonged Equipment Lifespan:

Gold-plated components are susceptible to corrosion and wear over time, which can lead to performance degradation and even failure of electrical heating equipment. The gold removal and re-tinning oven machine effectively removes the deteriorated gold layer, allowing for re-tinning to restore the components' functionality and extend their lifespan. By incorporating this machine into your maintenance routine, you can mitigate the risk of premature equipment failure and enhance the longevity of your electrical heating devices.

3. Versatile Applications:

The gold removal and re-tinning oven machine find applications across various electrical heating equipment, including soldering irons, heating elements, and melting furnaces. Regardless of the specific device or its intricacies, this versatile tool can efficiently remove gold plating and re-tin the components, providing a viable solution for a wide range of equipment in the industry. Embrace this technology to address gold plating concerns and ensure the superior performance of your electrical heating devices.

4. Cost-Effective Solution:

Rather than replacing gold-plated components, which can be costly and time-consuming, the gold removal and re-tinning oven machine offer a cost-effective alternative. By rejuvenating the existing components, this technology eliminates the need for expensive replacements, reducing overall maintenance expenses. Additionally, it enables you to utilize your equipment for an extended duration, maximizing your return on investment and minimizing operational disruptions.

In conclusion, the gold removal and re-tinning oven machine revolutionize the electrical heating equipment industry by enhancing efficiency, prolonging equipment lifespan, offering versatile applications, and providing a cost-effective solution. Incorporating this advanced technology into your operations can unlock numerous benefits and ensure optimal performance of your devices. Embrace the power of this innovative tool and elevate your electrical heating equipment to new heights.

In the realm of electrical heating equipment, the gold removal and re-tinning oven machine plays a crucial role in optimizing performance and extending the longevity of various devices. This article explores the significance of this innovative tool and its applications within the industry. Discover how this advanced technology can benefit your electrical heating equipment and elevate your operations to new heights.

1. Enhanced Efficiency:

The gold removal and re-tinning oven machine are designed to remove gold plating from various components, ensuring optimal conductivity and enhancing overall efficiency. By eliminating the gold layer, the machine facilitates a more effective flow of electricity, reducing energy losses and improving the performance of electrical heating devices. With this technology, you can unlock greater efficiency and maximize your equipment's output.

2. Prolonged Equipment Lifespan:

Gold-plated components are susceptible to corrosion and wear over time, which can lead to performance degradation and even failure of electrical heating equipment. The gold removal and re-tinning oven machine effectively removes the deteriorated gold layer, allowing for re-tinning to restore the components' functionality and extend their lifespan. By incorporating this machine into your maintenance routine, you can mitigate the risk of premature equipment failure and enhance the longevity of your electrical heating devices.

3. Versatile Applications:

The gold removal and re-tinning oven machine find applications across various electrical heating equipment, including soldering irons, heating elements, and melting furnaces. Regardless of the specific device or its intricacies, this versatile tool can efficiently remove gold plating and re-tin the components, providing a viable solution for a wide range of equipment in the industry. Embrace this technology to address gold plating concerns and ensure the superior performance of your electrical heating devices.

4. Cost-Effective Solution:

Rather than replacing gold-plated components, which can be costly and time-consuming, the gold removal and re-tinning oven machine offer a cost-effective alternative. By rejuvenating the existing components, this technology eliminates the need for expensive replacements, reducing overall maintenance expenses. Additionally, it enables you to utilize your equipment for an extended duration, maximizing your return on investment and minimizing operational disruptions.

In conclusion, the gold removal and re-tinning oven machine revolutionize the electrical heating equipment industry by enhancing efficiency, prolonging equipment lifespan, offering versatile applications, and providing a cost-effective solution. Incorporating this advanced technology into your operations can unlock numerous benefits and ensure optimal performance of your devices. Embrace the power of this innovative tool and elevate your electrical heating equipment to new heights.

gold removal and re-tinning oven machine

undefined