28

2023

-

08

Achieve Superior Soldering Results using Laser Solder Wire Soldering Machine

Author:

Table of Contents: 1. Introduction: The Importance of Superior Soldering Results 2. Understanding the Laser Solder Wire Soldering Machine 3. How Laser Solder Wire Soldering Machines Work 4. Advantages of Laser Solder Wire Soldering Machines 5. Choosing the Right Laser Solder Wire Soldering Machine 6. Tips and Techniques for Achieving Superior Soldering Results 7. Frequently Asked Questions (FAQs)

Table of Contents:

1. Introduction: The Importance of Superior Soldering Results

2. Understanding the Laser Solder Wire Soldering Machine

3. How Laser Solder Wire Soldering Machines Work

4. Advantages of Laser Solder Wire Soldering Machines

5. Choosing the Right Laser Solder Wire Soldering Machine

6. Tips and Techniques for Achieving Superior Soldering Results

7. Frequently Asked Questions (FAQs)

8. Conclusion: Elevate Your Soldering Work with Laser Solder Wire Soldering Machines

1. Introduction: The Importance of Superior Soldering Results

When it comes to soldering, achieving superior results is crucial for ensuring the reliability and longevity of electronic components. Whether you're an electronics enthusiast, a professional electrician, or a manufacturer, the quality of your solder joints can significantly impact the performance of the devices you work on.

In this article, we will explore the power of laser solder wire soldering machines and how they can revolutionize your soldering work. By harnessing the precision and efficiency of laser technology, these machines offer unprecedented control, speed, and reliability, allowing you to achieve superior soldering results consistently.

2. Understanding the Laser Solder Wire Soldering Machine

A laser solder wire soldering machine is a cutting-edge tool designed to simplify and enhance the soldering process. It utilizes a high-powered laser beam to heat the solder wire, melting it and creating a strong bond between the components.

Unlike traditional soldering methods that rely on irons or hot air, laser solder wire soldering machines deliver heat directly to the solder joint, minimizing the risk of overheating or damaging sensitive components. The laser beam is precisely targeted, ensuring that the heat is concentrated on the desired area, resulting in clean and reliable solder joints.

3. How Laser Solder Wire Soldering Machines Work

Laser solder wire soldering machines utilize advanced laser technology to achieve superior soldering results. The machine consists of a laser source, a solder wire feeder, and a control system.

First, the solder wire is fed into the machine through a feeder mechanism. The laser beam is then focused on the solder joint, rapidly heating the wire and the components to their melting point. The solder wire flows into the joint, creating a strong and durable connection.

The control system of the machine allows you to adjust various parameters, such as laser power, pulse duration, and spot size, to optimize the soldering process for different materials and applications.

4. Advantages of Laser Solder Wire Soldering Machines

Using a laser solder wire soldering machine offers numerous advantages over traditional soldering methods. Here are some key benefits:

a. Precision: Laser technology enables precise control over the soldering process, resulting in consistent and reliable solder joints.

b. Speed: Laser solder wire soldering machines are significantly faster than manual soldering methods, increasing productivity and efficiency.

c. Versatility: These machines can be used for a wide range of soldering applications, including surface mount technology (SMT), through-hole soldering, and wire bonding.

d. Quality: Laser solder wire soldering machines produce high-quality solder joints with minimal defects, reducing the chances of rework or failures.

e. Automation: Some advanced laser solder wire soldering machines offer automation capabilities, allowing for batch soldering and integration into production lines.

5. Choosing the Right Laser Solder Wire Soldering Machine

When selecting a laser solder wire soldering machine, several factors need to be considered:

a. Power and Energy: Higher laser power and energy levels provide faster and more efficient soldering, especially for larger or more complex solder joints.

b. Beam Delivery: The machine should offer precise beam delivery options, such as adjustable spot sizes and focal lengths, to accommodate different soldering requirements.

c. Control System: Look for a machine with an intuitive control system that allows for easy adjustment of parameters and offers a user-friendly interface.

d. Safety Features: Laser solder wire soldering machines should have built-in safety features, such as interlocks and shielding, to protect the operator and prevent accidental exposure to laser radiation.

e. Maintenance and Support: Consider the availability of maintenance services and technical support when choosing a machine, as regular maintenance is essential for optimal performance.

6. Tips and Techniques for Achieving Superior Soldering Results

To maximize the benefits of a laser solder wire soldering machine and achieve superior soldering results, here are some tips and techniques to keep in mind:

a. Proper Preparation: Ensure that the surfaces to be soldered are clean, free of contaminants, and properly aligned.

b. Choosing the Right Solder Wire: Select the appropriate solder wire for the application, considering factors such as material compatibility, flux type, and diameter.

c. Optimizing Laser Parameters: Experiment with different laser power, pulse duration, and spot size settings to find the optimal parameters for your specific soldering needs.

d. Adequate Ventilation: Maintain a well-ventilated workspace to prevent the accumulation of solder fumes and ensure the operator's safety.

e. Regular Calibration and Maintenance: Follow the manufacturer's guidelines for calibration and maintenance to ensure the machine operates at its peak performance.

7. Frequently Asked Questions (FAQs)

Q1: Are laser solder wire soldering machines suitable for both small-scale and industrial applications?

A1: Yes, laser solder wire soldering machines can be used for various applications, from small-scale repairs to industrial production.

Q2: Can laser solder wire soldering machines be used with different solder alloys?

A2: Yes, these machines are compatible with a wide range of solder alloys, such as lead-free solders and specialized alloys.

Q3: Are laser solder wire soldering machines safe to use?

A3: Laser solder wire soldering machines are designed with safety features to minimize the risk of accidents. However, it is crucial to follow safety guidelines and wear appropriate protective equipment.

Q4: Can laser solder wire soldering machines replace traditional soldering methods entirely?

A4: While laser solder wire soldering machines offer numerous advantages, they may not be suitable for all soldering applications. Traditional soldering methods may still be preferred in certain situations.

Q5: Can laser solder wire soldering machines be integrated into automated production lines?

A5: Yes, some advanced laser solder wire soldering machines offer automation capabilities, making them suitable for integration into production lines.

8. Conclusion: Elevate Your Soldering Work with Laser Solder Wire Soldering Machines

In conclusion, laser solder wire soldering machines are a game-changer in the world of soldering. By harnessing laser technology, these machines offer unparalleled precision, speed, and reliability, allowing you to achieve superior soldering results consistently.

Whether you're working on electronics repairs, manufacturing intricate circuit boards, or any other soldering application, investing in a laser solder wire soldering machine can significantly elevate the quality and efficiency of your work. Choose the right machine for your needs, follow best practices, and unleash the power of laser soldering technology to take your soldering skills to new heights.

1. Introduction: The Importance of Superior Soldering Results

2. Understanding the Laser Solder Wire Soldering Machine

3. How Laser Solder Wire Soldering Machines Work

4. Advantages of Laser Solder Wire Soldering Machines

5. Choosing the Right Laser Solder Wire Soldering Machine

6. Tips and Techniques for Achieving Superior Soldering Results

7. Frequently Asked Questions (FAQs)

8. Conclusion: Elevate Your Soldering Work with Laser Solder Wire Soldering Machines

1. Introduction: The Importance of Superior Soldering Results

When it comes to soldering, achieving superior results is crucial for ensuring the reliability and longevity of electronic components. Whether you're an electronics enthusiast, a professional electrician, or a manufacturer, the quality of your solder joints can significantly impact the performance of the devices you work on.

In this article, we will explore the power of laser solder wire soldering machines and how they can revolutionize your soldering work. By harnessing the precision and efficiency of laser technology, these machines offer unprecedented control, speed, and reliability, allowing you to achieve superior soldering results consistently.

2. Understanding the Laser Solder Wire Soldering Machine

A laser solder wire soldering machine is a cutting-edge tool designed to simplify and enhance the soldering process. It utilizes a high-powered laser beam to heat the solder wire, melting it and creating a strong bond between the components.

Unlike traditional soldering methods that rely on irons or hot air, laser solder wire soldering machines deliver heat directly to the solder joint, minimizing the risk of overheating or damaging sensitive components. The laser beam is precisely targeted, ensuring that the heat is concentrated on the desired area, resulting in clean and reliable solder joints.

3. How Laser Solder Wire Soldering Machines Work

Laser solder wire soldering machines utilize advanced laser technology to achieve superior soldering results. The machine consists of a laser source, a solder wire feeder, and a control system.

First, the solder wire is fed into the machine through a feeder mechanism. The laser beam is then focused on the solder joint, rapidly heating the wire and the components to their melting point. The solder wire flows into the joint, creating a strong and durable connection.

The control system of the machine allows you to adjust various parameters, such as laser power, pulse duration, and spot size, to optimize the soldering process for different materials and applications.

4. Advantages of Laser Solder Wire Soldering Machines

Using a laser solder wire soldering machine offers numerous advantages over traditional soldering methods. Here are some key benefits:

a. Precision: Laser technology enables precise control over the soldering process, resulting in consistent and reliable solder joints.

b. Speed: Laser solder wire soldering machines are significantly faster than manual soldering methods, increasing productivity and efficiency.

c. Versatility: These machines can be used for a wide range of soldering applications, including surface mount technology (SMT), through-hole soldering, and wire bonding.

d. Quality: Laser solder wire soldering machines produce high-quality solder joints with minimal defects, reducing the chances of rework or failures.

e. Automation: Some advanced laser solder wire soldering machines offer automation capabilities, allowing for batch soldering and integration into production lines.

5. Choosing the Right Laser Solder Wire Soldering Machine

When selecting a laser solder wire soldering machine, several factors need to be considered:

a. Power and Energy: Higher laser power and energy levels provide faster and more efficient soldering, especially for larger or more complex solder joints.

b. Beam Delivery: The machine should offer precise beam delivery options, such as adjustable spot sizes and focal lengths, to accommodate different soldering requirements.

c. Control System: Look for a machine with an intuitive control system that allows for easy adjustment of parameters and offers a user-friendly interface.

d. Safety Features: Laser solder wire soldering machines should have built-in safety features, such as interlocks and shielding, to protect the operator and prevent accidental exposure to laser radiation.

e. Maintenance and Support: Consider the availability of maintenance services and technical support when choosing a machine, as regular maintenance is essential for optimal performance.

6. Tips and Techniques for Achieving Superior Soldering Results

To maximize the benefits of a laser solder wire soldering machine and achieve superior soldering results, here are some tips and techniques to keep in mind:

a. Proper Preparation: Ensure that the surfaces to be soldered are clean, free of contaminants, and properly aligned.

b. Choosing the Right Solder Wire: Select the appropriate solder wire for the application, considering factors such as material compatibility, flux type, and diameter.

c. Optimizing Laser Parameters: Experiment with different laser power, pulse duration, and spot size settings to find the optimal parameters for your specific soldering needs.

d. Adequate Ventilation: Maintain a well-ventilated workspace to prevent the accumulation of solder fumes and ensure the operator's safety.

e. Regular Calibration and Maintenance: Follow the manufacturer's guidelines for calibration and maintenance to ensure the machine operates at its peak performance.

7. Frequently Asked Questions (FAQs)

Q1: Are laser solder wire soldering machines suitable for both small-scale and industrial applications?

A1: Yes, laser solder wire soldering machines can be used for various applications, from small-scale repairs to industrial production.

Q2: Can laser solder wire soldering machines be used with different solder alloys?

A2: Yes, these machines are compatible with a wide range of solder alloys, such as lead-free solders and specialized alloys.

Q3: Are laser solder wire soldering machines safe to use?

A3: Laser solder wire soldering machines are designed with safety features to minimize the risk of accidents. However, it is crucial to follow safety guidelines and wear appropriate protective equipment.

Q4: Can laser solder wire soldering machines replace traditional soldering methods entirely?

A4: While laser solder wire soldering machines offer numerous advantages, they may not be suitable for all soldering applications. Traditional soldering methods may still be preferred in certain situations.

Q5: Can laser solder wire soldering machines be integrated into automated production lines?

A5: Yes, some advanced laser solder wire soldering machines offer automation capabilities, making them suitable for integration into production lines.

8. Conclusion: Elevate Your Soldering Work with Laser Solder Wire Soldering Machines

In conclusion, laser solder wire soldering machines are a game-changer in the world of soldering. By harnessing laser technology, these machines offer unparalleled precision, speed, and reliability, allowing you to achieve superior soldering results consistently.

Whether you're working on electronics repairs, manufacturing intricate circuit boards, or any other soldering application, investing in a laser solder wire soldering machine can significantly elevate the quality and efficiency of your work. Choose the right machine for your needs, follow best practices, and unleash the power of laser soldering technology to take your soldering skills to new heights.

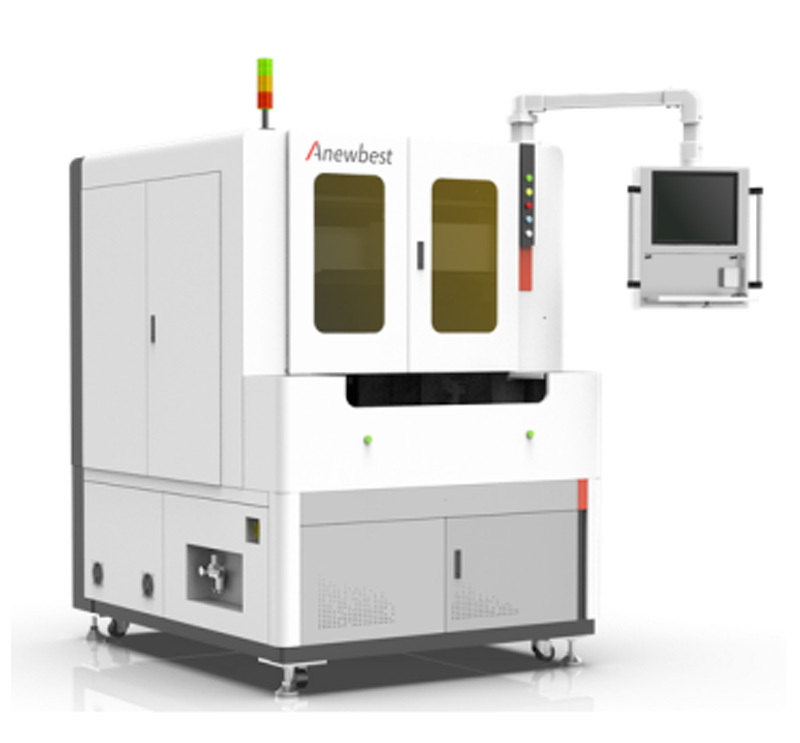

Laser solder wire soldering machine

undefined