27

2023

-

08

Enhance Your Soldering Process with Laser Solder Wire Soldering Machine: A Revolutionary Approach to Precision Soldering

Author:

Table of Contents 1. Introduction: Embrace the Future of Soldering 2. How Does a Laser Solder Wire Soldering Machine Work? 3. Advantages of Laser Soldering 4. Applications of Laser Soldering 5. Factors to Consider When Choosing a Laser Solder Wire Soldering Machine 6. Frequently Asked Questions (FAQs) 7. Conclusion: Unleash the Power of Laser Soldering 1. Introduction: Embrace the Future of Solder

Table of Contents

1. Introduction: Embrace the Future of Soldering

2. How Does a Laser Solder Wire Soldering Machine Work?

3. Advantages of Laser Soldering

4. Applications of Laser Soldering

5. Factors to Consider When Choosing a Laser Solder Wire Soldering Machine

6. Frequently Asked Questions (FAQs)

7. Conclusion: Unleash the Power of Laser Soldering

1. Introduction: Embrace the Future of Soldering

In this technological era, precision and efficiency are of paramount importance in various industries, including electronics, automotive, aerospace, and more. The soldering process plays a crucial role in ensuring reliable connections and optimal performance of electronic components. However, traditional soldering methods often pose challenges in terms of precision and consistency. That's where the Laser Solder Wire Soldering Machine comes into play, revolutionizing the way soldering is done.

2. How Does a Laser Solder Wire Soldering Machine Work?

The Laser Solder Wire Soldering Machine utilizes advanced laser technology to melt solder wire and create strong, reliable connections with utmost precision. The machine emits a laser beam that is focused on the soldering point, generating intense heat that melts the solder wire. This precise and controlled process ensures minimal heat transfer to surrounding components, eliminating the risk of damage or overheating. By automating the soldering process, the machine guarantees consistent results and reduces human error.

3. Advantages of Laser Soldering

- Precision: The laser beam provides an incredibly accurate and focused heat source, allowing for precise soldering even on intricate and small components. This ensures optimal connection quality and reduces the chances of defects or rework.

- Speed: Laser soldering is significantly faster than traditional methods. The rapid melting and solidification of solder wire enable faster assembly and production processes, resulting in increased efficiency and productivity.

- Versatility: Laser soldering can be applied to a wide range of materials, including metals, ceramics, plastics, and more. It accommodates various solder wire types and fluxes, providing flexibility for different soldering applications.

- Cleanliness: The laser soldering process generates minimal smoke, flux residue, or splatter, resulting in cleaner and more aesthetically pleasing solder joints. This is particularly important in industries where visual inspection is crucial.

- Reliability: Laser soldering creates robust and durable solder joints with excellent mechanical and electrical properties. The precise control over heat input reduces the risk of cold solder joints or weak connections, ensuring long-term reliability.

4. Applications of Laser Soldering

The Laser Solder Wire Soldering Machine finds applications in numerous industries where precision and reliability are paramount. Some common applications include:

- Electronics manufacturing: Laser soldering is widely used in the production of circuit boards, semiconductors, and electronic devices. It enables precise and efficient soldering of delicate components, ensuring optimal functionality and longevity.

- Automotive industry: Laser soldering plays a crucial role in soldering automotive electronic systems, such as sensors, control units, and wiring harnesses. The reliable connections achieved through laser soldering contribute to improved vehicle performance and safety.

- Aerospace and aviation: In the aerospace industry, where reliability is critical, laser soldering ensures the secure soldering of components used in avionic systems, satellites, and other aerospace applications. It withstands extreme conditions and vibrations, ensuring optimal performance and longevity.

- Medical devices: Laser soldering is extensively used in the manufacturing of medical devices, such as pacemakers, hearing aids, and surgical instruments. The precision and cleanliness of laser soldering guarantee safe and reliable medical equipment.

- Jewelry industry: Laser soldering is employed in jewelry manufacturing to achieve precise and aesthetically pleasing solder joints, especially for delicate and intricate designs.

5. Factors to Consider When Choosing a Laser Solder Wire Soldering Machine

When selecting a Laser Solder Wire Soldering Machine, consider the following factors to ensure the best fit for your specific requirements:

- Power and energy control: Look for machines that offer precise control over laser power and energy. This allows for flexibility in soldering various materials and components.

- Solder wire compatibility: Ensure that the machine supports the solder wire types and diameters required for your applications.

- Automation and programming capabilities: Consider machines with user-friendly interfaces, programmable settings, and automation features to enhance efficiency and ease of use.

- Safety features: Look for machines equipped with safety measures such as protective enclosures, interlocks, and real-time monitoring systems to ensure operator safety and prevent accidents.

- Service and support: Opt for machines from reputable manufacturers that provide comprehensive customer support, including maintenance, training, and spare parts availability.

6. Frequently Asked Questions (FAQs)

Q1: Is laser soldering suitable for all soldering applications?

Q2: Can laser soldering be used on heat-sensitive components?

Q3: How does laser soldering compare to other soldering methods in terms of cost?

Q4: Can laser soldering replace traditional soldering methods completely?

Q5: How long does it take to master laser soldering?

7. Conclusion: Unleash the Power of Laser Soldering

The Laser Solder Wire Soldering Machine offers a game-changing solution for enhancing soldering processes across various industries. Its precision, speed, and versatility make it a valuable asset in achieving reliable and efficient soldering results. By embracing the power of laser soldering, you can elevate the quality of your soldering projects, increase productivity, and stay ahead in this competitive era of advanced manufacturing. Explore the possibilities with a Laser Solder Wire Soldering Machine and unlock new levels of excellence in your soldering process.

1. Introduction: Embrace the Future of Soldering

2. How Does a Laser Solder Wire Soldering Machine Work?

3. Advantages of Laser Soldering

4. Applications of Laser Soldering

5. Factors to Consider When Choosing a Laser Solder Wire Soldering Machine

6. Frequently Asked Questions (FAQs)

7. Conclusion: Unleash the Power of Laser Soldering

1. Introduction: Embrace the Future of Soldering

In this technological era, precision and efficiency are of paramount importance in various industries, including electronics, automotive, aerospace, and more. The soldering process plays a crucial role in ensuring reliable connections and optimal performance of electronic components. However, traditional soldering methods often pose challenges in terms of precision and consistency. That's where the Laser Solder Wire Soldering Machine comes into play, revolutionizing the way soldering is done.

2. How Does a Laser Solder Wire Soldering Machine Work?

The Laser Solder Wire Soldering Machine utilizes advanced laser technology to melt solder wire and create strong, reliable connections with utmost precision. The machine emits a laser beam that is focused on the soldering point, generating intense heat that melts the solder wire. This precise and controlled process ensures minimal heat transfer to surrounding components, eliminating the risk of damage or overheating. By automating the soldering process, the machine guarantees consistent results and reduces human error.

3. Advantages of Laser Soldering

- Precision: The laser beam provides an incredibly accurate and focused heat source, allowing for precise soldering even on intricate and small components. This ensures optimal connection quality and reduces the chances of defects or rework.

- Speed: Laser soldering is significantly faster than traditional methods. The rapid melting and solidification of solder wire enable faster assembly and production processes, resulting in increased efficiency and productivity.

- Versatility: Laser soldering can be applied to a wide range of materials, including metals, ceramics, plastics, and more. It accommodates various solder wire types and fluxes, providing flexibility for different soldering applications.

- Cleanliness: The laser soldering process generates minimal smoke, flux residue, or splatter, resulting in cleaner and more aesthetically pleasing solder joints. This is particularly important in industries where visual inspection is crucial.

- Reliability: Laser soldering creates robust and durable solder joints with excellent mechanical and electrical properties. The precise control over heat input reduces the risk of cold solder joints or weak connections, ensuring long-term reliability.

4. Applications of Laser Soldering

The Laser Solder Wire Soldering Machine finds applications in numerous industries where precision and reliability are paramount. Some common applications include:

- Electronics manufacturing: Laser soldering is widely used in the production of circuit boards, semiconductors, and electronic devices. It enables precise and efficient soldering of delicate components, ensuring optimal functionality and longevity.

- Automotive industry: Laser soldering plays a crucial role in soldering automotive electronic systems, such as sensors, control units, and wiring harnesses. The reliable connections achieved through laser soldering contribute to improved vehicle performance and safety.

- Aerospace and aviation: In the aerospace industry, where reliability is critical, laser soldering ensures the secure soldering of components used in avionic systems, satellites, and other aerospace applications. It withstands extreme conditions and vibrations, ensuring optimal performance and longevity.

- Medical devices: Laser soldering is extensively used in the manufacturing of medical devices, such as pacemakers, hearing aids, and surgical instruments. The precision and cleanliness of laser soldering guarantee safe and reliable medical equipment.

- Jewelry industry: Laser soldering is employed in jewelry manufacturing to achieve precise and aesthetically pleasing solder joints, especially for delicate and intricate designs.

5. Factors to Consider When Choosing a Laser Solder Wire Soldering Machine

When selecting a Laser Solder Wire Soldering Machine, consider the following factors to ensure the best fit for your specific requirements:

- Power and energy control: Look for machines that offer precise control over laser power and energy. This allows for flexibility in soldering various materials and components.

- Solder wire compatibility: Ensure that the machine supports the solder wire types and diameters required for your applications.

- Automation and programming capabilities: Consider machines with user-friendly interfaces, programmable settings, and automation features to enhance efficiency and ease of use.

- Safety features: Look for machines equipped with safety measures such as protective enclosures, interlocks, and real-time monitoring systems to ensure operator safety and prevent accidents.

- Service and support: Opt for machines from reputable manufacturers that provide comprehensive customer support, including maintenance, training, and spare parts availability.

6. Frequently Asked Questions (FAQs)

Q1: Is laser soldering suitable for all soldering applications?

Q2: Can laser soldering be used on heat-sensitive components?

Q3: How does laser soldering compare to other soldering methods in terms of cost?

Q4: Can laser soldering replace traditional soldering methods completely?

Q5: How long does it take to master laser soldering?

7. Conclusion: Unleash the Power of Laser Soldering

The Laser Solder Wire Soldering Machine offers a game-changing solution for enhancing soldering processes across various industries. Its precision, speed, and versatility make it a valuable asset in achieving reliable and efficient soldering results. By embracing the power of laser soldering, you can elevate the quality of your soldering projects, increase productivity, and stay ahead in this competitive era of advanced manufacturing. Explore the possibilities with a Laser Solder Wire Soldering Machine and unlock new levels of excellence in your soldering process.

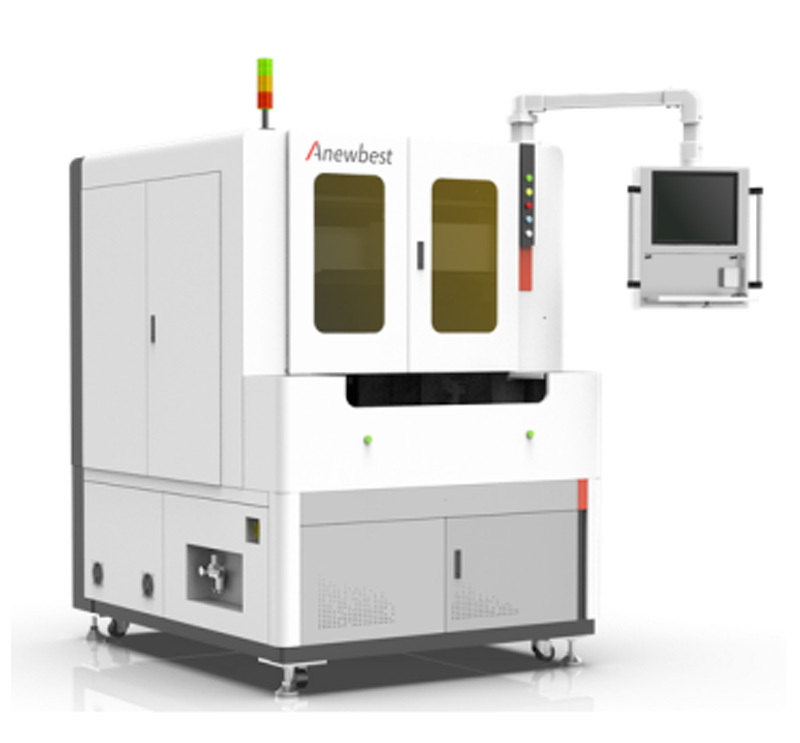

Laser solder wire soldering machine

undefined